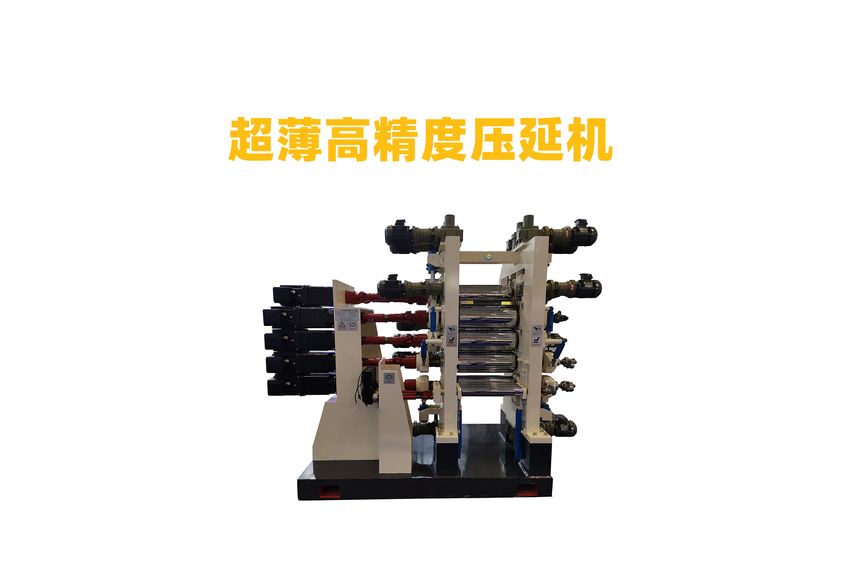

The Rubber Four Roller Press: A Detailed Guide to Its Function, Applications, and Maintenance

The rubber four roller press is a crucial piece of machinery in the rubber industry, used for various applications such as vulcanization, extrusion, and shaping. This article will provide an in-depth understanding of this machine, its functions, applications, and maintenance requirements.

Function:

The rubber four roller press is a versatile tool that can be used for a variety of tasks. It is primarily used for vulcanization, where it applies heat and pressure to rubber compounds to convert them into a solid state. This process is essential in the production of tires, hoses, and other rubber products. In addition to vulcanization, the four roller press can also be used for extrusion, where it applies heat and pressure to molten rubber to form a continuous thread or tube. Finally, it can be used for shaping, where it applies pressure to a sheet of rubber to create a desired shape.

Applications:

The rubber four roller press is widely used in the rubber industry due to its ability to perform multiple functions. It is commonly found in tire factories, where it is used to vulcanize tires before they are assembled onto wheels. In addition, it is also used in the production of hoses, belts, and other rubber products. Furthermore, it can be used in the automotive industry for the production of brake pads and other rubber components.

Maintenance:

To ensure the longevity and efficiency of the rubber four roller press, proper maintenance is essential. Here are some key maintenance tips:

1. Regular inspection: Regular inspection of the machine is necessary to identify any potential issues before they become major problems. This includes checking for wear on the rollers, adjusting the tension on the rolls, and inspecting the temperature sensors.

2. Lubrication: Proper lubrication is crucial for maintaining the smooth operation of the machine. Ensure that the bearings and rollers are properly lubricated to prevent wear and tear.

3. Cleaning: Regular cleaning of the machine is necessary to remove any debris or contaminants that could damage the machine or affect its performance.

4. Replacement parts: Regular replacement of worn-out parts is necessary to maintain the machine's efficiency and safety. Check the manufacturer's specifications for recommended parts and replace them when necessary.

1. Rubber four roller press

2. Vulcanization

3. Extrusion

4. Shaping

5. Maintenance

The Rubber Four Roller Press is a critical piece of machinery in the rubber industry, used for various applications such as vulcanization, extrusion, and shaping. This article provides an in-depth understanding of this machine, highlighting its functions, applications, and maintenance requirements. By following these tips, you can ensure the longevity and efficiency of your rubber four roller press, allowing you to produce high-quality rubber products efficiently and effectively.