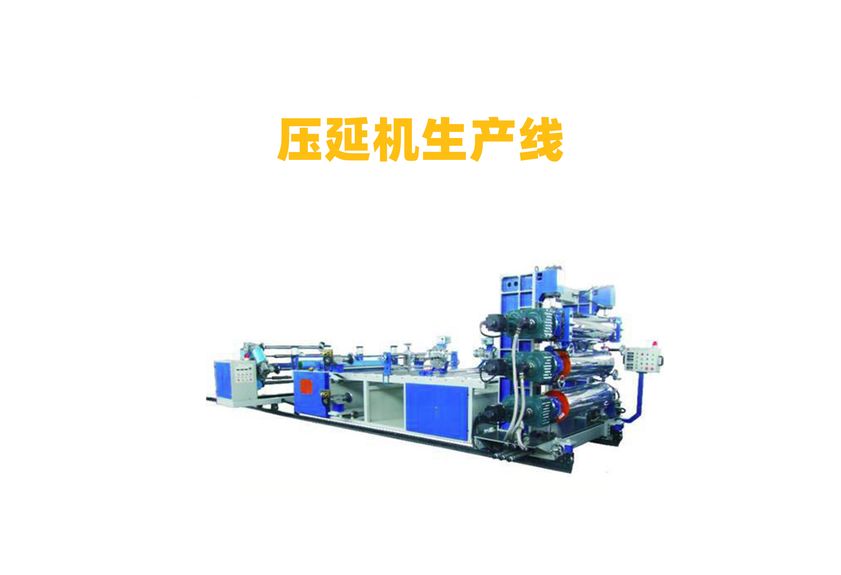

PTFE拉伸压延机:工业应用中的创新技术

The PTFE (Polytetrafluoroethylene) stretch and roll press is a cutting-edge technology that has revolutionized the manufacturing industry. This machine is designed to process thermoplastic polytetrafluoroethylene, also known as Teflon, into various shapes and sizes with high precision and efficiency.

One of the key features of the PTFE stretch and roll press is its ability to handle a wide range of materials, including a variety of plastics, rubbers, and composites. The machine's advanced control system allows for precise temperature regulation and pressure adjustment, ensuring that the processed material meets the highest quality standards.

In addition to its technical capabilities, the PTFE stretch and roll press is also highly versatile in terms of its applications. It can be used to produce parts for aerospace, automotive, electronics, and other industries, where durability, strength, and resistance to chemicals are critical factors.

Another advantage of this machine is its ability to produce complex geometries and intricate designs. With its advanced software and algorithms, the PTFE stretch and roll press can create parts that are difficult or impossible to manufacture using traditional methods.

Overall, the PTFE stretch and roll press represents a significant advancement in the field of polymer processing. Its combination of advanced technology, high precision, and versatility makes it an essential tool for companies looking to improve their product quality and reduce costs. As the demand for high-quality, durable materials continues to grow, the PTFE stretch and roll press will undoubtedly play a crucial role in shaping the future of the manufacturing industry.