The Art of Rubber Roll Compounding Machinery

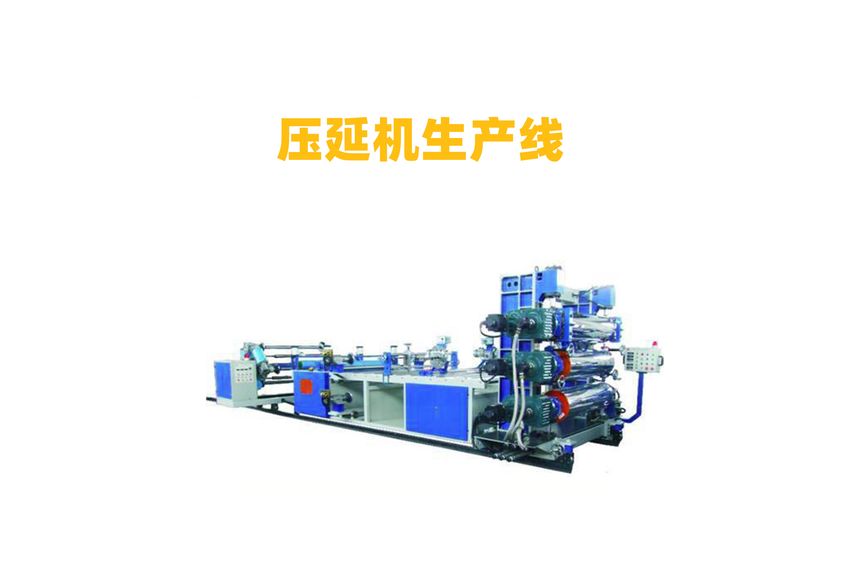

The rubber roll compounding machine is a crucial tool in the manufacturing industry, specifically in the production of rubber products. This machine uses four rollers to press and blend two or more rubber compounds together, resulting in a uniform, high-quality product.

The first step in using this machine is to load the raw materials into the hopper. These materials can include natural rubber, synthetic rubber, and other additives such as carbon black or fillers. Once the materials are loaded, the machine begins to operate.

The first roller in the machine is responsible for spreading the material evenly across the surface of the second roller. This process is known as "compounding." As the material moves from the first roller to the second roller, it is subjected to heat and pressure, which causes the rubber molecules to bond together.

The second roller then applies pressure to the material, pressing it down onto the third roller. This process repeats until the material is completely pressed down onto the fourth roller. At this point, the material is ready to be cut and packaged for use.

One of the key benefits of using a rubber roll compounding machine is that it produces a consistent product every time. This consistency is important for many applications, including automotive, aerospace, and construction industries.

In addition to its technical benefits, the rubber roll compounding machine also has a significant impact on the environment. By reducing waste and using renewable energy sources, manufacturers can reduce their carbon footprint and contribute to a more sustainable future.

Overall, the rubber roll compounding machine is an essential tool in the manufacturing industry, providing consistent, high-quality products while also contributing to a more sustainable future.