Understanding the Thermal Dissipation Performance of Graphite Film Rolling Machines

The thermal dissipation performance of a graphite film rolling machine is critical for its efficiency and longevity. This article will explore the various factors that contribute to the cooling capabilities of this innovative technology, which has become increasingly important in modern electronics manufacturing.

Firstly, the design of the graphite film itself plays a significant role in its thermal dissipation properties. The thickness, density, and porosity of the graphite film all influence its ability to conduct heat away from the device being processed. For example, a thinner or denser film may have better thermal conductivity, allowing for faster heat transfer to the surrounding air or other cooling medium. Additionally, the porosity of the film can impact its overall thermal performance, as it allows for more efficient heat exchange between the film and the surrounding environment.

Secondly, the operating conditions of the graphite film rolling machine also play a crucial role in determining its thermal dissipation capabilities. For instance, high temperatures or high humidity levels can reduce the effectiveness of the cooling system, while low temperatures or dry conditions can enhance it. It is therefore essential to monitor and control these variables to ensure optimal performance throughout the entire process.

Thirdly, the choice of cooling medium is another critical factor that affects the thermal dissipation performance of the graphite film rolling machine. Different cooling agents have varying heat transfer rates and specific heat capacities, so selecting the appropriate one is essential for achieving optimal cooling results. Additionally, the flow rate and pressure of the cooling medium can also impact its effectiveness in removing heat from the device being processed.

Finally, the overall design and construction of the graphite film rolling machine itself can also affect its thermal dissipation capabilities. For example, incorporating advanced materials such as copper or aluminum into the machine's components can improve heat conduction and dissipation, while using advanced manufacturing techniques can create more efficient cooling channels and structures.

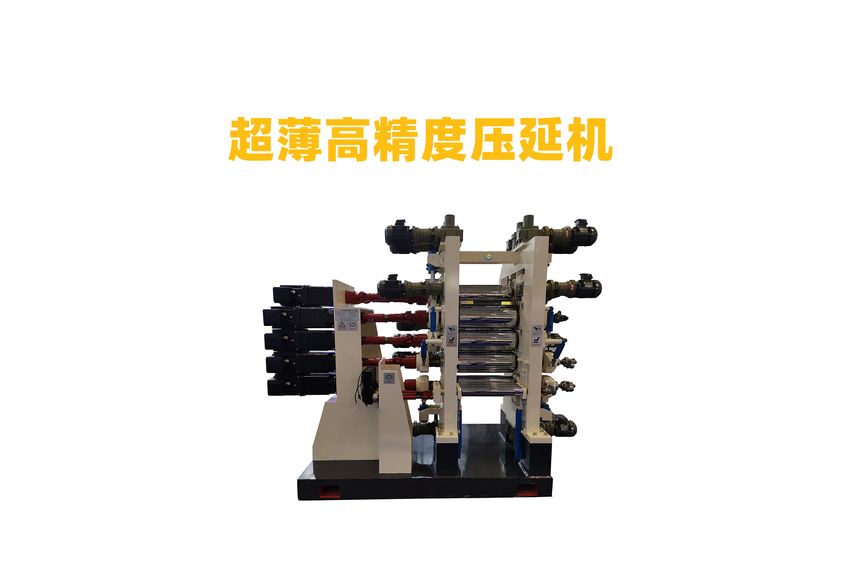

1. Graphite Film Rolling Machine

2. Thermal Dissipation Performance

3. Cooling Mechanisms

4. Heat Conduction

5. Manufacturing Techniques

This article provides an in-depth analysis of the thermal dissipation performance of graphite film rolling machines, highlighting the key factors that contribute to their effective cooling capabilities. By examining the design, operating conditions, cooling medium selection, and overall machine construction, we aim to provide readers with valuable insights into how to optimize the thermal dissipation performance of these innovative machines. Whether you are a manufacturer looking to improve your product's cooling efficiency or a researcher interested in exploring new cooling technologies, this article will provide you with the knowledge and tools necessary to achieve your goals.