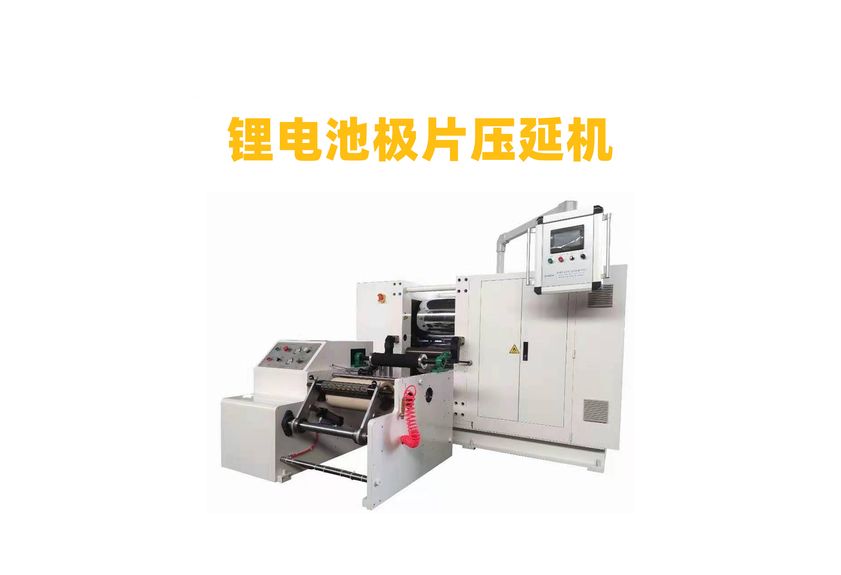

The Role of Lithium Battery Pulley Pressing Machine in the Manufacturing Process

Lithium batteries are one of the most popular energy storage systems due to their high energy density, long cycle life, and environmental friendliness. However, the production process of lithium batteries involves several complex steps, including electrode preparation, assembly, and testing. Among these steps, the manufacture of lithium battery electrodes is crucial for ensuring the quality and performance of the final product. In this article, we will discuss the role of a lithium battery pouch-cell pressing machine in the manufacturing process of lithium battery electrodes.

The pouch-cell pressing machine is an essential tool in the production process of lithium battery electrodes. It is used to compress the active material and conductive additives into a uniform and compact structure on the surface of the electrode. This process helps to improve the contact between the active material and the current collector, which is crucial for the efficient transfer of electrons during charging and discharging. Additionally, the pouch-cell pressing machine can also help to remove any air bubbles or impurities from the active material, further improving the performance of the electrode.

In addition to its role in preparing the electrode, the pouch-cell pressing machine is also important for the overall quality and safety of the lithium battery. By using a controlled pressure and temperature during the pressing process, the machine ensures that the active material is evenly distributed across the electrode surface, resulting in a more stable and reliable battery performance. Moreover, the pouch-cell pressing machine can also help to prevent any potential hazards such as short circuits or overheating, which could occur if the active material is not properly processed.

In conclusion, the pouch-cell pressing machine plays a vital role in the manufacturing process of lithium battery electrodes. By compressing the active material and conductive additives into a uniform and compact structure, it helps to improve the contact between the active material and the current collector, and remove any air bubbles or impurities. This process not only enhances the performance of the electrode but also contributes to the overall quality and safety of the lithium battery. Therefore, investing in a high-quality pouch-cell pressing machine is essential for any manufacturer looking to produce high-quality lithium battery electrodes.