The Art of Rubber Rolling Pressing Machines

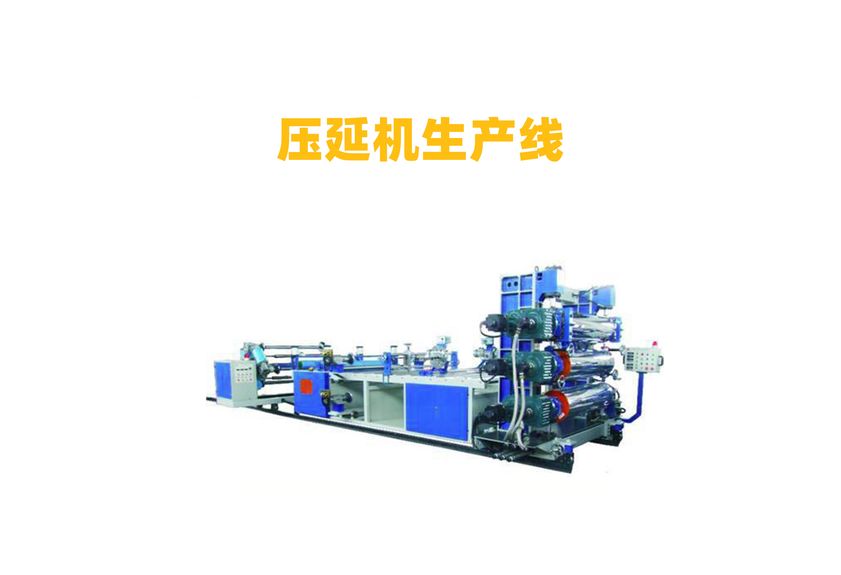

The rubber rolling pressing machine is a crucial tool in the manufacturing industry, particularly in the production of rubber products. This machine uses five rollers to press and shape rubber sheets into various shapes and sizes, making it an essential part of the rubber processing process. In this article, we will explore the working principle of a rubber rolling pressing machine and its applications in the rubber industry.

The rubber rolling pressing machine works by using hydraulic pressure to press the rubber sheets between two rollers. These rollers are mounted on a frame that rotates around a central axis. As the frame rotates, the rubber sheets are forced against each other, causing them to deform and become more uniform in thickness and width. The pressure applied by the rollers can be adjusted to control the degree of deformation and shape of the rubber sheets.

One of the main advantages of a rubber rolling pressing machine is its ability to produce high-quality rubber sheets with consistent thickness and width. This makes it ideal for use in the production of tires, hoses, gloves, and other rubber products. By using this machine, manufacturers can save time and money while still producing high-quality products.

In addition to its practical applications, the rubber rolling pressing machine also has a history dating back to ancient times. It was first used by the ancient Greeks to make leather shoes and boots. Over time, it evolved into modern-day machines that are used in the rubber industry today.

When selecting a rubber rolling pressing machine, it is important to consider factors such as the size of the sheets being processed, the desired shape of the product, and the type of rollers needed. Some machines may have adjustable rollers that allow for customization of the final product's appearance. Additionally, it is important to choose a machine that is reliable and easy to maintain, as this will ensure that the rubber sheets produced are of high quality and consistent in size and shape.

1. Rubber Rolling Pressing Machine

2. Rubber Product Manufacturing

3. Hydraulic Pressure

4. Deformation

5. Thickness Control

The article provides an in-depth exploration of the working principle and applications of rubber rolling pressing machines in the rubber industry. It highlights the importance of these machines in producing high-quality rubber sheets with consistent thickness and width, which are essential for the production of various rubber products. The article also discusses the historical development of this technology and the factors to consider when selecting a suitable machine. With its practical applications and reliability, the rubber rolling pressing machine remains a critical tool in the manufacturing industry.