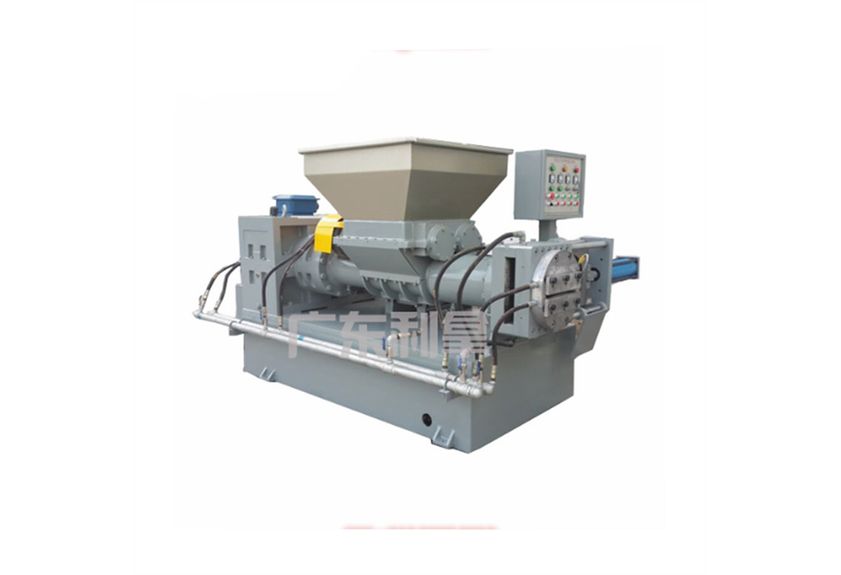

Understanding the Forced Feed Extruder and Its Applications

The forced feed extruder is a crucial equipment in the plastics industry, primarily used for the production of various types of plastic products. It is a high-speed screw extruder that uses a force to push the material through the die, which is then cooled and solidified into the desired shape. This process is essential in creating products such as pipes, profiles, and moldings.

One of the key features of the forced feed extruder is its ability to handle a wide range of materials, including thermoplastics, thermosets, and even metals. The extruder's design allows for precise control over the temperature and pressure during the extrusion process, ensuring that the final product meets the required specifications.

In addition to its technical capabilities, the forced feed extruder also has a significant impact on the environment. By using less energy and producing fewer waste products, it helps to reduce the carbon footprint associated with plastic production. Furthermore, the use of recycled materials in the production process further contributes to sustainability.

Overall, the forced feed extruder is an essential tool in the plastics industry, providing reliable and efficient solutions for the production of a wide range of plastic products. Its ability to handle a variety of materials and produce high-quality products makes it an ideal choice for businesses looking to expand their operations or improve their existing processes.