Understanding the Forced Feed Extruder

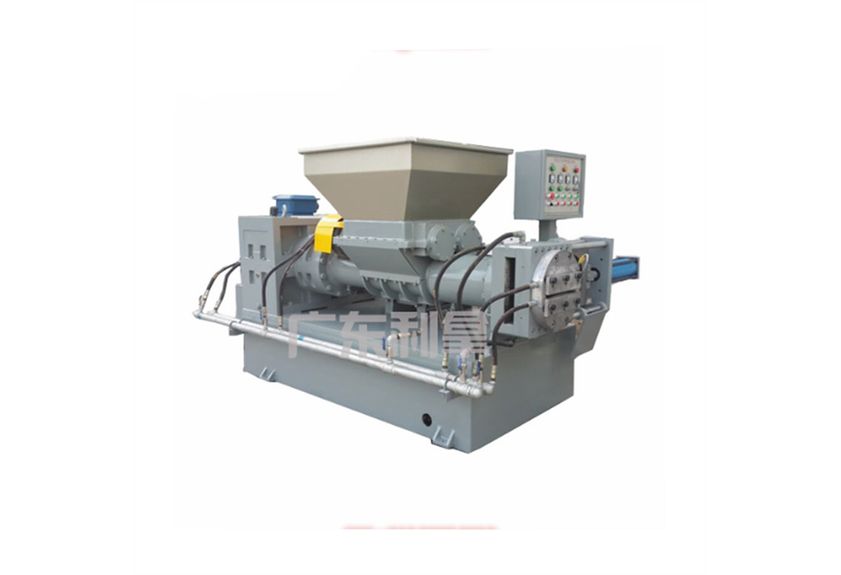

The forced feed extruder is a crucial component in the manufacturing industry, particularly in the food and beverage sector. This machine is designed to process materials such as starch, sugar, and other polymers into uniformly shaped products. The process involves feeding raw materials into the extruder, which then forces them through a die, resulting in the formation of a solid product. The force applied by the extruder is essential for ensuring that the material is evenly distributed throughout the product.

One of the key features of the forced feed extruder is its ability to handle different types of materials with ease. This makes it ideal for producing a wide range of products, from plastic bottles to food packaging. Additionally, the extruder's precision control system ensures that the product's consistency and quality are consistent across all production runs.

In addition to its technical benefits, the forced feed extruder also has a significant impact on the environment. By reducing waste and minimizing energy consumption, these machines can help reduce greenhouse gas emissions and contribute to a more sustainable future. As the demand for eco-friendly products continues to grow, the importance of using these efficient machines cannot be overstated.

1. Forced Feed Extruder

2. Manufacturing Industry

3. Food and Beverage Sector

4. Polymer Processing

5. Eco-Friendly Products

The article provides an in-depth understanding of the Forced Feed Extruder, highlighting its role in the manufacturing industry and its ability to process various types of materials. It discusses the benefits of using this efficient machine, including its ability to produce consistent products and minimize waste. Additionally, the article emphasizes the importance of using eco-friendly machines in today's environmentally conscious society.