"The Role of Teflon Rolling Mills in Polytetrafluoroethylene Production

Teflon, also known as polytetrafluoroethylene (PTFE), is a synthetic polymer with exceptional properties that make it widely used in various industries. One of the key processes involved in producing PTFE is the extrusion process, which involves the use of a machine called a teflon rolling mill. This article will provide an overview of the teflon rolling mill and its role in the production of PTFE.

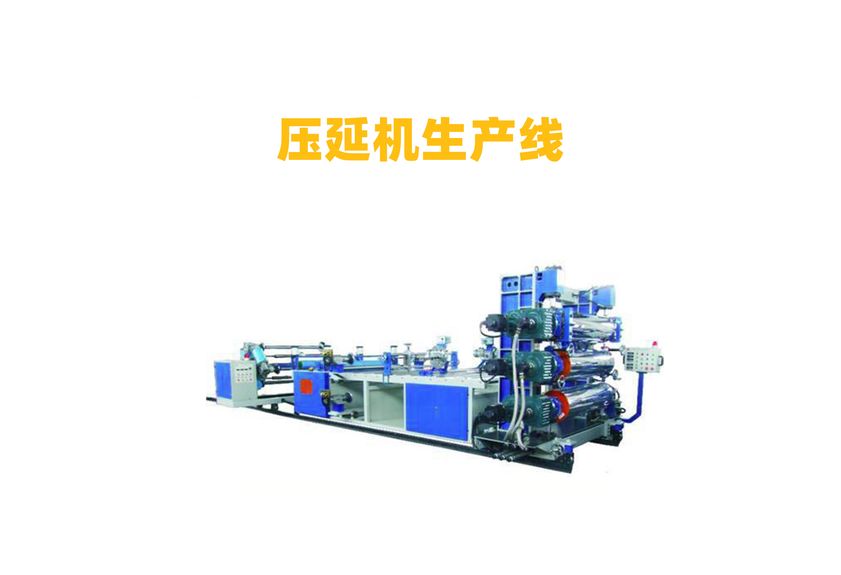

The teflon rolling mill is a specialized piece of equipment used to extrude PTFE into thin sheets or films. It consists of a rotating cylinder made of Teflon material, which is heated to a high temperature to soften the polymer. The molten polymer then flows through a die, which defines the shape of the final product. As the polymer cools and solidifies, it forms a continuous sheet or film, which can be further processed into various shapes and sizes.

One of the main advantages of using a teflon rolling mill is its ability to produce high-quality PTFE products with minimal defects. The process is highly precise and controlled, allowing for consistent results every time. Additionally, the use of Teflon as the material for the rolling mill ensures that the final product is free from any harmful chemicals or impurities, making it safe for use in various applications.

Another significant benefit of using a teflon rolling mill is its flexibility in terms of product customization. By adjusting the parameters of the process, such as the temperature, pressure, and speed, manufacturers can create PTFE products with specific properties and applications. For example, they can produce sheets with different thicknesses, textures, and finishes, which can be used in various industrial applications, including aerospace, medical devices, and electronics.

In conclusion, the teflon rolling mill plays a crucial role in the production of PTFE by providing a reliable and efficient way to extrude the polymer into thin sheets or films. Its precision, consistency, and flexibility make it an essential tool for the modern chemical industry, enabling manufacturers to produce high-quality products that meet the needs of various applications.