The Cut-Pulp Water Flow Production Line

The cutting-pulp water flow production line is a crucial component in the food industry, particularly in the production of granular products such as rice and pasta. This article will provide an overview of this line, highlighting its key features, benefits, and how it contributes to the overall efficiency and quality of the final product.

Firstly, let's define what a cut-pulp water flow production line is. It is a series of machines designed to process rice or pasta into their final granular form. This involves cutting the rice or pasta into small pieces, then mixing them with water to create a paste that can be molded into desired shapes. The resulting product is then dried and packaged for sale.

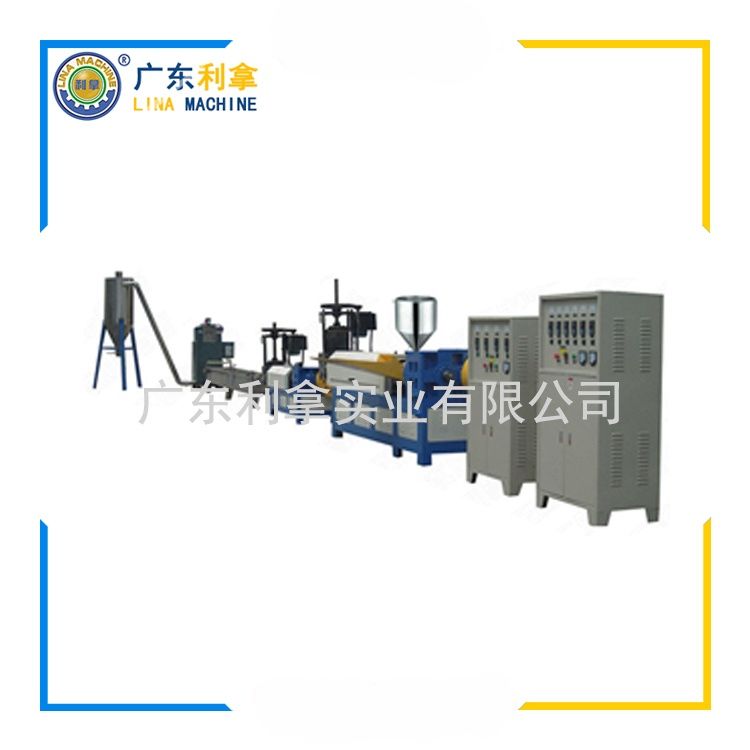

The main components of a cut-pulp water flow production line include the cutting machine, mixing machine, drying equipment, and packaging machinery. Each of these machines plays a critical role in ensuring the quality and consistency of the final product.

The cutting machine is responsible for breaking down the rice or pasta into small pieces. It uses a variety of cutting techniques, including knife blades, rollers, and shear bars, depending on the type of product being produced. The cutting process is crucial as it determines the size and shape of the final product.

The mixing machine is used to combine the rice or pasta with water to create a paste. This step is essential as it helps to bind the ingredients together and create a uniform texture. The mixing process also ensures that the final product has a consistent moisture content.

The drying equipment is used to remove any excess moisture from the paste before it is packaged. This is important as excessive moisture can lead to spoilage and loss of quality. The drying process can be done using various methods, including hot air drying, freeze drying, or spray drying.

Finally, the packaging machinery is used to package the final product in individual servings. This can be done using a variety of methods, including plastic bags, boxes, or trays. The packaging process is important as it helps to protect the product from contamination and ensure that it stays fresh for longer periods of time.

Benefits of a cut-pulp water flow production line include increased efficiency, improved product quality, and reduced waste. By using this line, manufacturers can produce granular products more quickly and efficiently than traditional methods. This can result in lower production costs and higher profit margins.

In addition, a cut-pulp water flow production line can help to reduce waste by minimizing the amount of raw materials used and by producing a product with a consistent quality. This can help to improve customer satisfaction and loyalty, as well as increase market share.

In conclusion, the cut-pulp water flow production line is a vital component of the food industry. Its key features, benefits, and contribution to overall efficiency and quality are all worth considering when considering new or existing manufacturing processes. By investing in this line, manufacturers can not only improve their production capabilities but also enhance the overall quality and consistency of their products.