Degradable Plastic Pellet Making Machine

The PLA (Polylactic Acid) degradation plastic is a type of biodegradable plastic that can be decomposed into natural substances like water and carbon dioxide when exposed to the environment. This technology has gained significant attention in recent years due to its eco-friendly properties and potential applications in various industries. In this article, we will explore the details of the PLA degradation plastic pellet making machine, including its design, working principles, and advantages.

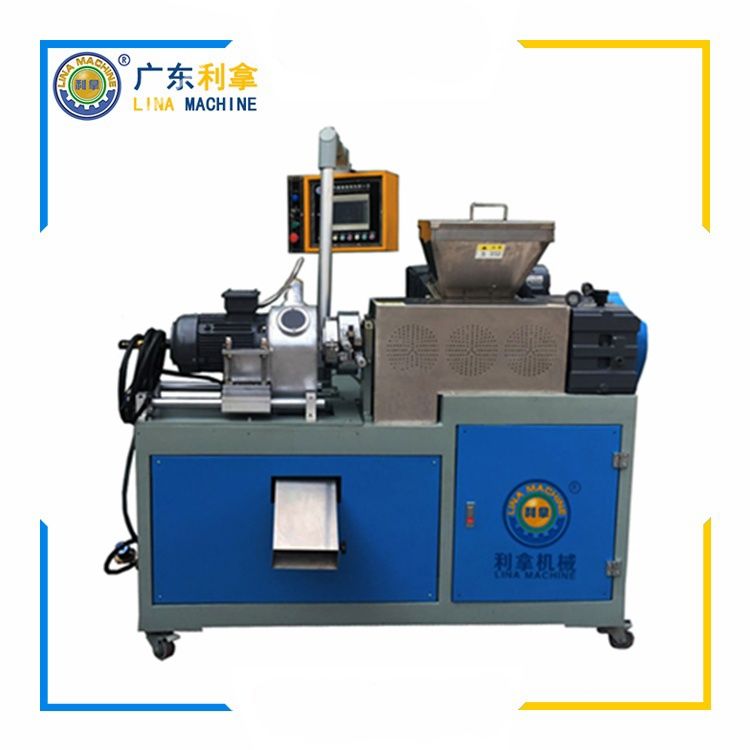

Design and Structure:

The PLA degradation plastic pellet making machine is designed to meet the needs of different production scales. It typically consists of several key components such as the feeding system, melting system, cooling system, granulating system, and packaging system. The feeding system is responsible for feeding raw materials into the machine, while the melting system converts these raw materials into a molten state. The cooling system then cools down the molten plastic to form pellets. The granulating system processes the pellets into uniformly sized pellets, while the packaging system packages the pellets for further use.

Working Principle:

The working principle of the PLA degradation plastic pellet making machine is based on heat and pressure. During the process, raw materials are fed into the machine through a hopper, where they are melted by the high-temperature heating system. The melted plastic then passes through a series of rollers and nozzles to form pellets. The size and shape of the pellets can be adjusted by adjusting the parameters of the granulating system. Once the pellets reach the desired size, they are cooled down by the cooling system and packaged for storage or transportation.

Advantages:

Compared to traditional petroleum-based plastics, PLA degradation plastics have several advantages. Firstly, they are biodegradable, which means they can be broken down naturally by microorganisms in the soil and water. This reduces the environmental pollution caused by non-biodegradable plastics. Secondly, PLA degradation plastics have excellent mechanical properties, such as high strength, toughness, and flexibility, which make them suitable for a wide range of applications in engineering, agriculture, and other fields. Finally, PLA degradation plastics have low cost and easy recycling, which makes them more competitive in the market.

Conclusion:

In conclusion, the PLA degradation plastic pellet making machine is an important tool for producing biodegradable plastic pellets. With its efficient design and unique working principle, it can meet the needs of various industries and contribute to sustainable development. As the demand for biodegradable plastics continues to increase, the PLA degradation plastic pellet making machine will play an increasingly important role in the future.