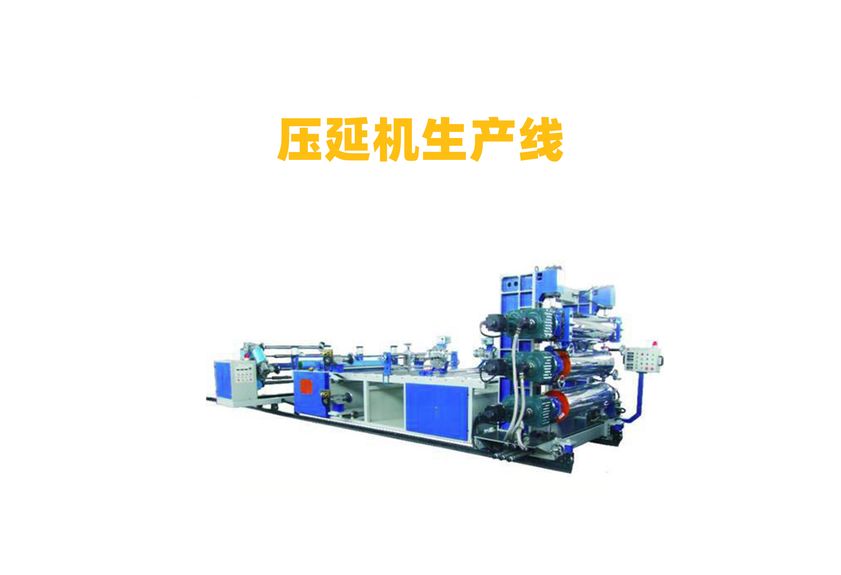

Liquid Thermal Conductive Silicone Rolling Machine

The liquid thermal conductive silicone rolling machine is a crucial tool in the manufacturing industry, particularly in the electronics and aerospace sectors. This machine is designed to roll and shape liquid thermal conductive silicone sheets into various shapes and sizes, which are then used in heat exchangers, thermal interface materials, and other thermal management applications.

The liquid thermal conductive silicone is a unique material that combines the thermal conductivity of metals with the flexibility of polymers. It has excellent thermal conductivity, making it an ideal choice for heat transfer applications where efficiency is critical. The liquid state of the silicone allows for easy shaping and molding, making it possible to create complex geometries that are difficult or impossible to achieve with traditional solid materials.

The liquid thermal conductive silicone rolling machine consists of several key components. The first is the roller assembly, which is responsible for applying pressure and shaping the silicone sheet. The rollers are made from high-quality materials such as stainless steel or ceramic, ensuring durability and longevity. The second component is the heating system, which provides the necessary heat energy to melt the silicone and allow it to flow freely. The third component is the cooling system, which helps to maintain the temperature of the silicone sheet during processing.

The liquid thermal conductive silicone rolling machine operates by first loading the silicone sheet into the machine's hopper. The operator then selects the desired shape and size for the silicone sheet using a computer-controlled software interface. The machine then begins to process the silicone sheet, applying pressure and heat to shape it according to the specifications. Once the silicone sheet is finished, it is ejected from the machine and stored for further use.

In conclusion, the liquid thermal conductive silicone rolling machine is a powerful tool for the manufacturing industry, allowing for the creation of high-performance thermal management materials. Its ability to process liquid silicone sheets and create complex geometries makes it an essential piece of equipment for companies in the electronics, aerospace, and other industries that require efficient heat transfer solutions.