The Role of Lithium Battery Pulley Pressing Machines in the Manufacturing Process

The production of lithium batteries is a complex process that requires precise and consistent manufacturing techniques. One of the key steps in this process is the manufacture of the battery's active material, which is usually made up of thin layers of metal or alloy. These layers are then stacked together to form the battery's electrodes. In order to ensure that these layers are evenly distributed and aligned with each other, the active material must be subjected to a series of mechanical processes. One such process is the use of a lithium battery pulley pressing machine.

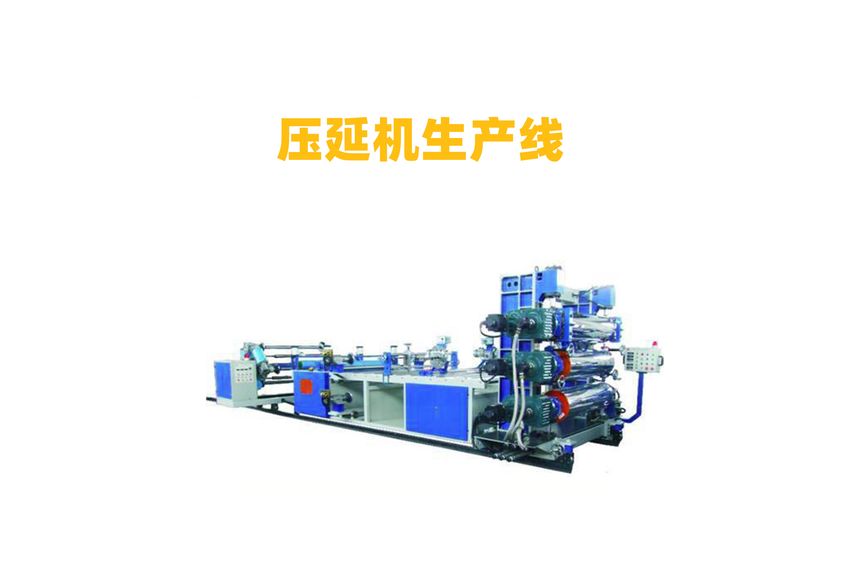

A lithium battery pulley pressing machine is a specialized piece of equipment that is used to compress and shape the active material into the desired shape. This machine uses a high-pressure roller to apply force to the material, which causes it to flow and conform to the desired shape. The resulting product is then cooled and dried, and the active material is ready for further processing.

The importance of using a lithium battery pulley pressing machine cannot be overstated. Not only does it improve the quality of the final product, but it also reduces waste and increases efficiency. By using a machine, manufacturers can produce more uniform and consistent electrodes, which leads to better overall performance from their batteries. Additionally, the use of a pulley pressing machine can help to reduce costs by eliminating the need for manual labor and increasing production speed.

1. Lithium Battery Pulley Pressing Machine

2. Manufacturing Process

3. Active Material

4. Electrode Production

5. Cost Reduction

This article provides an in-depth look at the critical role played by lithium battery pulley pressing machines in the manufacturing process of lithium batteries. It discusses the importance of these machines in ensuring consistent and high-quality active material production, as well as their impact on reducing waste and increasing efficiency. The article highlights the benefits of using a pulley pressing machine, including improved product quality, reduced costs, and increased production speed. By providing valuable insights into the technology behind lithium battery manufacturing, this article aims to educate readers about the importance of investing in advanced manufacturing equipment.