The Art of Two Roll Pressing Machines

The two-roll pressing machine is a crucial tool in the manufacturing industry, particularly in the automotive and aerospace sectors. This versatile piece of machinery is designed to produce high-quality sheet metal parts with precision and efficiency. In this article, we will explore the working principles of a two-roll press, its components, and how it contributes to the overall production process.

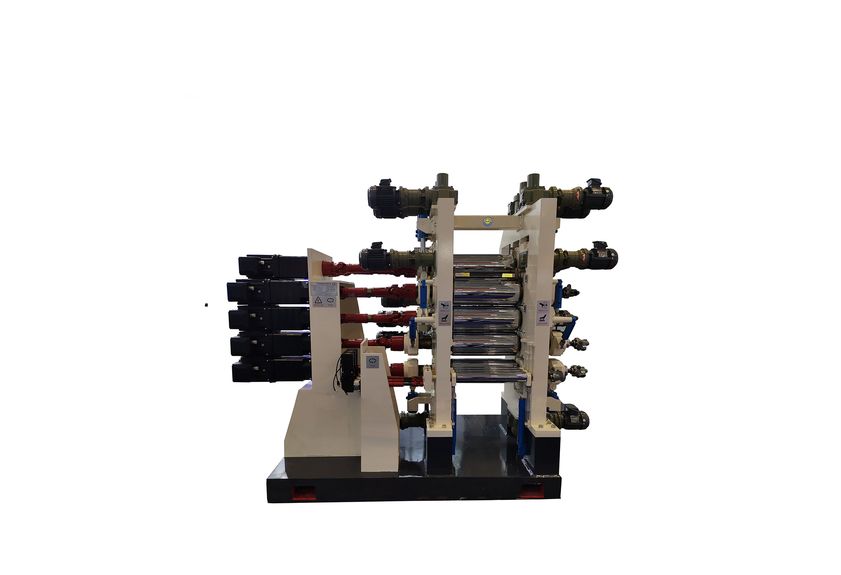

The two-roll press consists of two parallel steel rollers that are mounted on a frame. These rollers rotate at different speeds, creating a compressive force between them. As the material is fed into the press, it is forced between the rollers, which causes it to be flattened and deformed. This deformation is controlled by adjusting the pressure applied to the material and the distance between the rollers.

One of the key advantages of the two-roll press is its ability to produce precise dimensions and uniform thicknesses. By controlling the compressive force and the distance between the rollers, the machine can produce parts with consistent quality and accuracy. Additionally, the two-roll press is highly efficient, as it uses less energy compared to other methods of sheet metal processing.

In addition to its mechanical advantages, the two-roll press also has several components that contribute to its functionality. The frame, which supports the rollers and holds the material during the pressing process, is made from high-strength materials such as aluminum alloy or stainless steel. The drive mechanism, which converts electrical power into motion for the rollers, is typically powered by a motor and gearbox system. Finally, the control system, which monitors and regulates the pressing process, includes sensors and software that enable precise adjustments to the pressure and speed settings.

The two-roll press plays a vital role in many industries, including automotive, aerospace, and electronics. In the automotive industry, it is used to produce body panels, door panels, and interior trim pieces. In the aerospace industry, it is used to produce aircraft wings, fuselages, and other structural components. And in the electronics industry, it is used to produce circuit boards, connectors, and other electronic components.

In conclusion, the two-roll press is a versatile and efficient tool that has revolutionized the manufacturing industry. Its ability to produce precise dimensions and uniform thicknesses makes it an essential component in many industries. By understanding its working principles and components, manufacturers can optimize their production processes and achieve greater success in today's competitive market.