The Essentials of a Mixing Machine

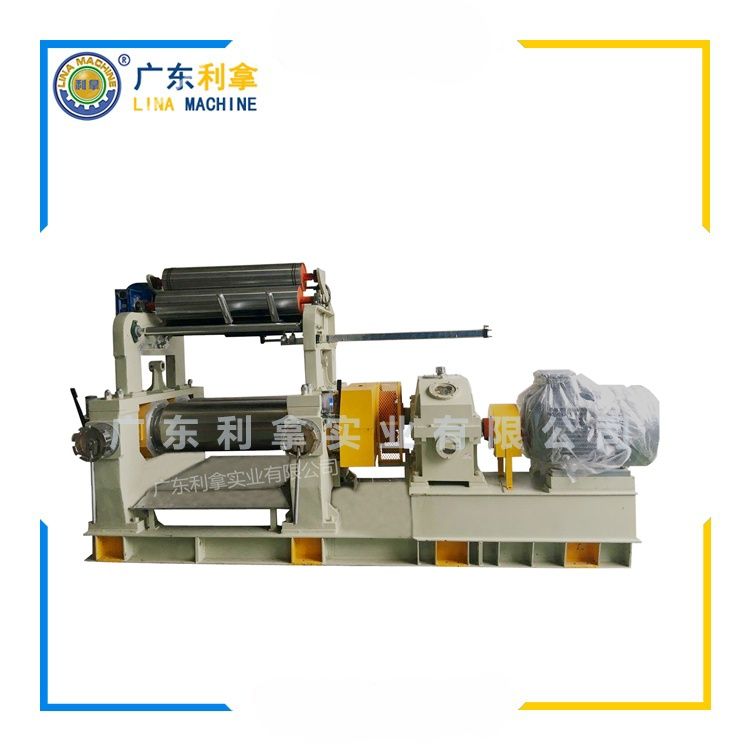

Mixing machines are an indispensable tool in the industrial world, serving as the backbone of many manufacturing processes. From food processing to pharmaceutical production, from plastic molding to metal casting, mixing machines play a crucial role in ensuring the consistency and quality of final products. In this article, we will delve into the fundamental aspects of a mixing machine, exploring its design, functionality, and applications.

Design and Functionality:

A typical mixer is designed to accommodate a variety of materials and processes, making it versatile and adaptable to different industries. The most common types of mixers include rotary, high-speed, and twin-screw. Rotary mixers are ideal for homogenizing and blending liquids, while high-speed mixers are suitable for mixing powders and granular materials. Twin-screw mixers are particularly effective for mixing viscous substances like paints and glues.

In terms of functionality, a mixer's primary goal is to achieve a uniform distribution of ingredients within the mixture. This can be achieved through various techniques, such as stirring, kneading, or dissolving. Some mixers also come with features that allow for temperature control, shear force adjustment, and even automation, making them highly efficient and precise.

Applications:

The applications of mixing machines are vast and varied, ranging from small-scale home projects to large-scale industrial processes. Here are just a few examples:

1. Food Processing: Mixers are essential tools in the food industry, allowing for the preparation of sauces, batters, doughs, and more. They ensure that ingredients are thoroughly mixed and combined to create consistent results every time.

2. Pharmaceutical Manufacturing: Mixers are used in the pharmaceutical industry to prepare suspensions, emulsions, and other complex formulations. They help to ensure that the active ingredients are evenly distributed throughout the product, improving its efficacy and safety.

3. Plastic Molding: Mixers are crucial in the plastics industry, where they are used to mix and distribute raw materials like polyethylene, polypropylene, and polystyrene into molds. This ensures that the final product has a consistent thickness and density.

4. Metal Casting: In the metal casting industry, mixers are used to mix molten metal with alloys and additives, creating a homogeneous and uniform mixture that can be poured into molds to produce parts with consistent properties.

1. Mixing Machine

2. Industrial Applications

3. Food Processing

4. Pharmaceutical Manufacturing

5. Plastic Molding

6. Metal Casting

7. Automation

8. Continuous Processing

9. Energy Efficiency

10. Cost-Effectiveness

This article provides an in-depth exploration of the essential components and functions of a mixing machine, highlighting its wide range of applications across various industries. From the design and functionality of different types of mixers to their diverse applications in food processing, pharmaceutical manufacturing, plastic molding, and metal casting, this article aims to provide readers with a comprehensive understanding of the importance of mixing machines in modern industrial processes. By highlighting the key features and benefits of each type of mixer, as well as their energy efficiency and cost-effectiveness, this article aims to inspire readers to consider investing in a mixing machine for their specific needs.