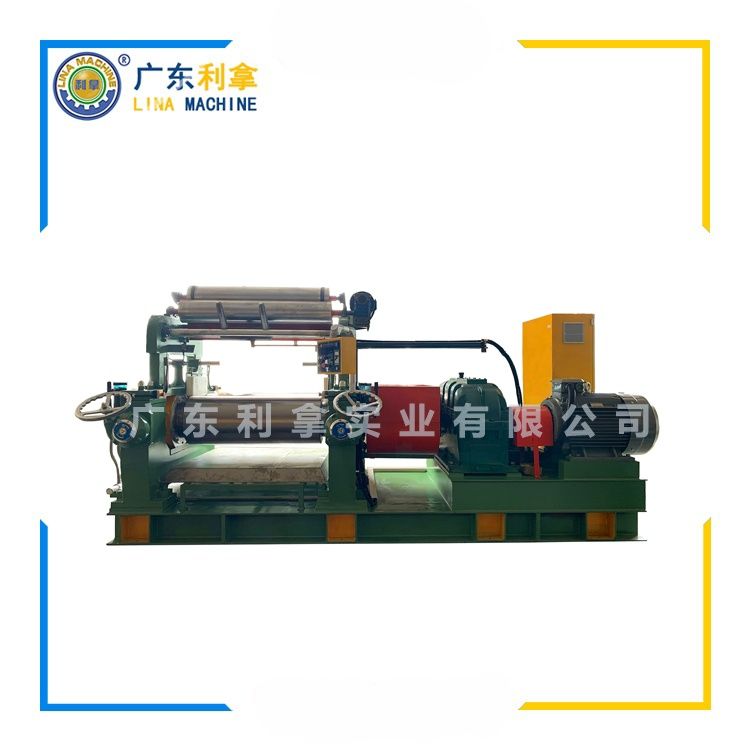

The Double Roll Mill: A Detailed Guide to Its Function and Applications

The double roll mill, also known as a two-roll mill, is an essential piece of machinery in the rubber industry. It is used for mixing, kneading, and extruding various types of rubber compounds, including natural and synthetic rubbers. In this article, we will explore the basic functions of the double roll mill, its applications, and some tips for maintaining it effectively.

Functions of the Double Roll Mill:

1. Mixing: The double roll mill is primarily used for mixing two or more rubber compounds together. This process helps to evenly distribute the ingredients and create a uniform mixture.

2. Kneading: The mill can also be used for kneading, which involves applying pressure to the mixture to form a dough-like consistency. This step is crucial for creating a smooth and consistent product.

3. Extrusion: The final stage of the process involves extruding the kneaded mixture into a desired shape, such as sheets, tubes, or molds. This allows for further processing and shaping of the final product.

Applications of the Double Roll Mill:

1. Rubber Compound Manufacturing: The double roll mill is widely used in the production of various types of rubber compounds, including vulcanized and unvulcanized rubbers.

2. Automotive Industry: In the automotive industry, the double roll mill is used to produce tires, belts, hoses, and other rubber components.

3. Construction Materials: The mill is also employed in the manufacturing of flooring, roofing, and other construction materials made from rubber.

4. Plastic Industry: In the plastic industry, the double roll mill is used to produce various types of plastic products, such as pipes, hoses, and valves.

5. Other Applications: The double roll mill can also be used in other industries, such as aerospace and electronics, where it is necessary to produce high-quality rubber products with precise specifications.

Tips for Maintaining the Double Roll Mill:

1. Regular Cleaning: To ensure that the mill operates efficiently, it is important to clean it regularly. This includes removing any debris from the rollers and other parts of the machine.

2. Lubrication: Proper lubrication is essential for preventing wear and tear on the mill's moving parts. Ensure that all bearings and gears are properly greased.

3. Regular Maintenance: Schedule regular maintenance checks to identify any potential issues before they become major problems. This may include checking the alignment of the rollers and adjusting them if necessary.

4. Proper Ventilation: Proper ventilation is important to prevent overheating of the mill during operation. Make sure there is adequate airflow around the machine.

5. Training: Have your operators trained in proper use and maintenance of the double roll mill. This will help ensure that they can identify and address any issues quickly and effectively.

1. Double roll mill

2. Rubber compound manufacturing

3. Automotive industry

4. Construction materials

5. Plastic industry

6. Regular cleaning

7. Proper lubrication

8. Regular maintenance

9. Proper ventilation

10. Training

The "Double Roll Mill" is a critical component in the rubber industry, specifically used for mixing, kneading, and extruding various types of rubber compounds. It plays a significant role in the production of tires, belts, hoses, and other rubber components used in various industries, including the automotive, construction, and plastic sectors. To maintain its efficiency and longevity, regular cleaning, proper lubrication, regular maintenance, proper ventilation, and training are essential practices. By following these guidelines, you can ensure that your "Double Roll Mill" remains a reliable and productive tool in your production line.