The Art of Silicone Rolling Presses

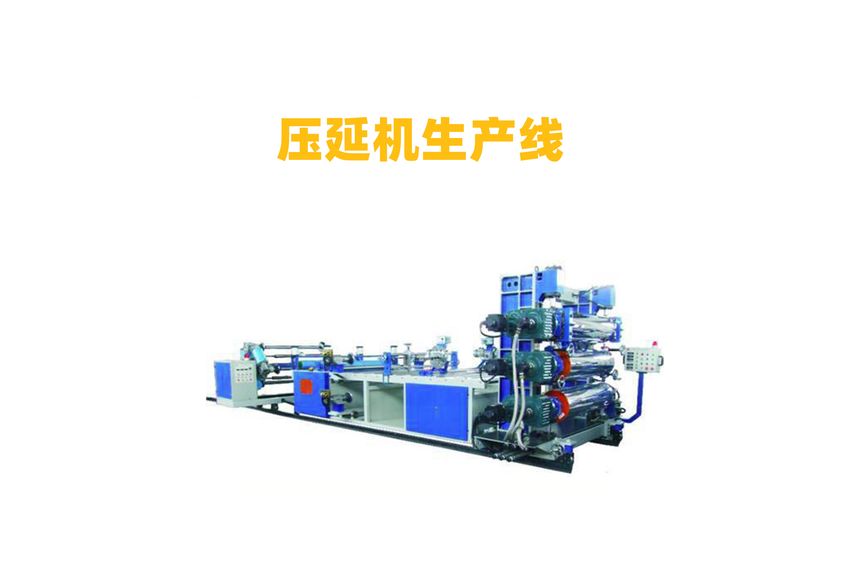

Silicone rolling presses are a crucial tool in the manufacturing industry, especially in the production of silicone products. These machines are designed to roll sheets of silicone rubber into thin, uniform films that can be used for various applications such as electronics, aerospace, and automotive industries. In this article, we will explore the different types of silicone rolling presses, their features, and how they contribute to the success of silicone product manufacturing.

Firstly, there are two main types of silicone rolling presses: continuous and discontinuous. Continuous rolling presses use a continuous sheet of silicone rubber to produce a continuous film, while discontinuous rolls use individual sheets of silicone rubber that are manually fed into the machine. Both types have their advantages and disadvantages, but continuous rolling presses are generally more efficient and cost-effective.

Continuous rolling presses are equipped with a series of rollers that rotate at high speeds to compress the silicone rubber sheet into a uniform film. The pressure applied by these rollers is carefully controlled to ensure that the film is not too thick or too thin. This ensures that the final product meets the required specifications and quality standards.

In addition to its mechanical design, the continuous rolling press also has a variety of other features that make it an ideal choice for silicone product manufacturing. For example, some models come with built-in cooling systems to prevent the silicone rubber from overheating during the compression process. Others feature automated feeding systems that ensure consistent sheet thickness and minimize waste.

Discontinuous rolling presses, on the other hand, are simpler in design but require manual handling of the individual sheets of silicone rubber. These machines are less efficient than continuous rolling presses but can still produce high-quality silicone films for certain applications.

The success of silicone rolling presses in silicone product manufacturing depends on several factors, including the type of silicone rubber used, the desired film thickness, and the specific application requirements. By understanding the different types of silicone rolling presses and their features, manufacturers can choose the right equipment to meet their specific needs and achieve optimal results.

1. silicone rolling presses

2. continuous rolling presses

3. discontinuous rolling presses

4. silicone rubber

5. manufacturing industry

This article provides an in-depth exploration of the art of silicone rolling presses, highlighting their importance in the manufacturing industry. We discuss the different types of silicone rolling presses, their features, and how they contribute to the success of silicone product manufacturing. Through this article, we aim to help readers understand the key aspects of silicone rolling presses and how they can benefit their business.