Graphene Thermal Conductive Pad Pressing Machine

The advent of graphene has revolutionized the field of electronics and energy storage, offering unprecedented thermal conductivity and mechanical strength. In the realm of electronic devices, such as smartphones, laptops, and tablets, the need for efficient heat dissipation has become paramount. This is where the graphene thermal conductive pad pressing machine comes into play.

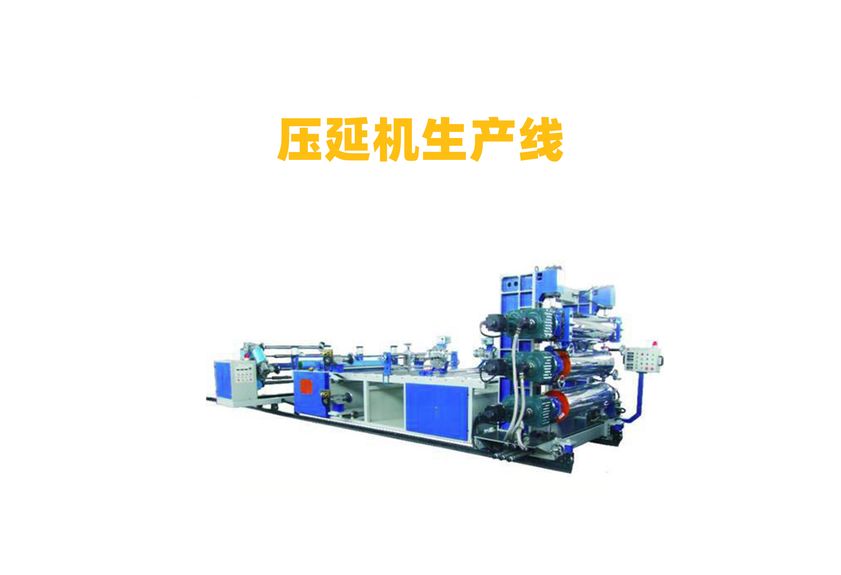

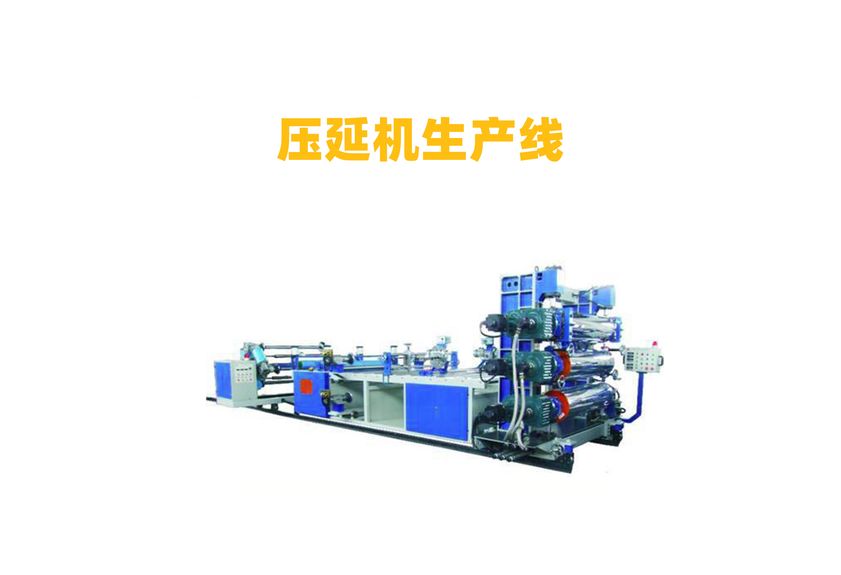

At its core, this machine utilizes a unique process that involves extruding graphene sheets onto a substrate. These sheets are then pressed together using high-pressure rollers to create a uniform layer of graphene on the surface. The result is a highly conductive and durable material that can significantly improve the overall thermal performance of electronic devices.

One of the key benefits of this technology is its ability to produce graphene in large quantities. Unlike traditional methods, which require expensive and time-consuming processes, this machine can produce graphene sheets with precise dimensions and thicknesses, making it ideal for use in various applications.

Another advantage of this machine is its flexibility in terms of customization. By adjusting the parameters of the process, manufacturers can tailor the properties of the graphene pads to meet specific requirements, such as temperature range or electrical conductivity. This allows for a wide range of applications, from wearable devices to high-performance sports equipment.

In addition to its technical advantages, the graphene thermal conductive pad pressing machine also offers significant cost savings. Compared to traditional methods, this technology requires less raw material and produces fewer waste products, making it more environmentally friendly.

Overall, the graphene thermal conductive pad pressing machine represents a significant advancement in the field of electronics and energy storage. Its ability to produce high-quality graphene at scale and customize it to meet specific needs makes it an essential tool for manufacturers looking to enhance their product's thermal performance. As the demand for efficient heat dissipation continues to grow, this technology will undoubtedly play a crucial role in shaping the future of electronics and energy storage.