The Flexible Plastic Pellet Production Line

The flexible plastic pellet production line is an essential tool in the manufacturing industry, particularly in the plastics and rubber sectors. This article will explore the various components of this line, their functions, and how they work together to produce high-quality plastic pellets.

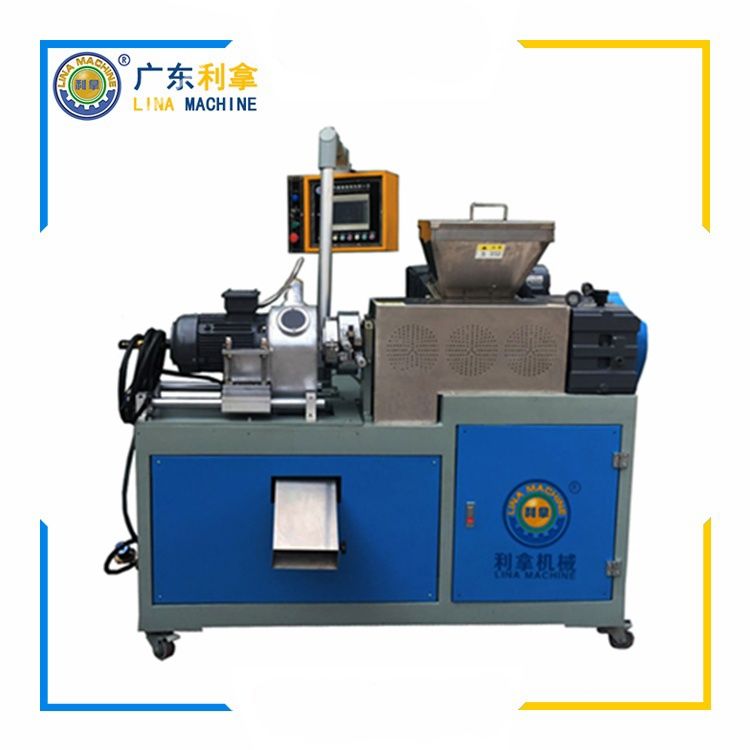

At the heart of the production line is the extruder, which is responsible for converting raw materials into a uniform, shaped product. The extruder uses heat and pressure to melt the plastic or rubber, which then flows through a die, where it is forced into a desired shape. The resulting product is a pellet that can be used as a feedstock for further processing.

The next step in the process is the cooling station, where the hot plastic or rubber is cooled down to its final temperature. This is crucial because it prevents the formation of undesirable crystalline structures that can affect the properties of the final product.

After cooling, the plastic or rubber is then granulated by a granulator. This process involves passing the material through a series of screens, which remove any larger particles and leave only the finer ones. The result is a uniformly sized pellet that can be easily handled and transported.

Finally, the finished pellet is packaged and stored for future use. This packaging should protect the pellet from moisture, dust, and other environmental factors that could affect its quality or shelf life.

1. Flexible Plastic Pellet Production Line

2. Extruder

3. Die

4. Cooling Station

5. Granulator

6. Packaging

7. Quality Control

8. Environmental Factors

9. Shelf Life

This article provides an in-depth look at the key components of a flexible plastic pellet production line, including the extruder, die, cooling station, granulator, and packaging process. It highlights the importance of quality control and environmental factors in ensuring the end product meets industry standards. By understanding these processes, readers can gain a better understanding of how plastic pellets are produced and how they can be used in various applications.