Understanding the Importance of Melt Blown Particle Extruders in Medical Devices

Melt blown particle extrusion is a crucial process in the production of medical devices, such as masks and surgical gowns. These machines are designed to produce high-quality melt-blown fabrics that meet stringent standards for sterilization and filtration. In this article, we will explore the different types of melt blowing machines available and their applications in the medical industry.

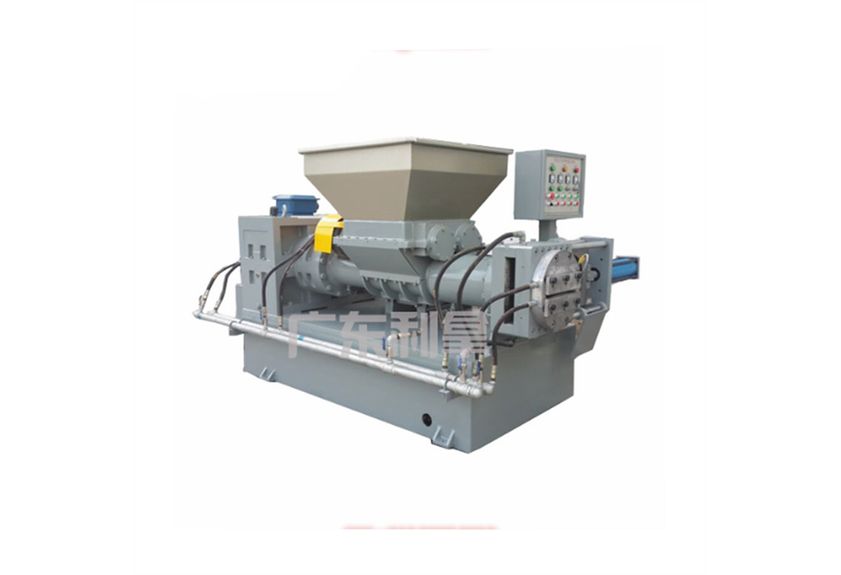

The first type of melt blown particle extruder is the single-screw extruder. This machine uses a single rotating screw to melt and extrude polymeric materials into fibers. The resulting fibers are then collected and formed into a continuous web. Single-screw extruders are commonly used in the production of surgical gowns and other protective clothing.

Another type of melt blown particle extruder is the twin-screw extruder. This machine has two rotating screws that work together to melt and extrude the polymeric material. The resulting fibers are then collected and formed into a continuous web. Twin-screw extruders are commonly used in the production of masks and other protective equipment.

In addition to these basic types of melt blown particle extruders, there are also specialized machines designed for specific applications. For example, some machines use air injection to create hollow fibers that can be filled with various materials, such as antimicrobial agents or absorbent materials. Other machines use water jetting to create microfibers that can be used in wound care products.

The importance of melt blown particle extrusion in the medical industry cannot be overstated. By using these machines, manufacturers can produce high-quality, sterilizable fabrics that meet the needs of healthcare professionals and patients. Additionally, these machines can help reduce the risk of infection by providing barrier protection against harmful pathogens.