The Art of Rubber Making: An Introduction to Rubber Processing Machines

Rubber is a versatile material that has found its way into countless products, from automobile tires to medical devices. Its unique properties make it an essential component in various industries. One crucial step in the rubber production process is the use of rubber processing machines. These machines are designed to convert raw materials into high-quality rubber products. In this article, we will explore the different types of rubber processing machines and their roles in the rubber industry.

The first type of rubber processing machine is the vulcanization machine. This machine is used to cure or vulcanize rubber, which involves heating the rubber to a certain temperature and pressure to achieve a hard, durable material. Vulcanization is a critical step in the production of tires, hoses, and other rubber products.

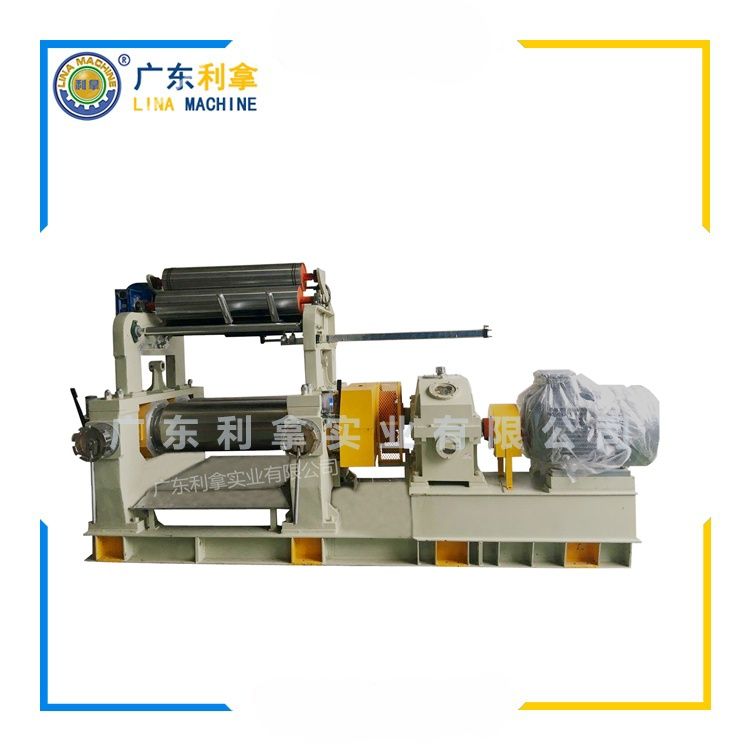

Another important type of rubber processing machine is the mixing machine. This machine is used to mix different rubber compounds together, such as natural rubber and synthetic rubber. Mixing is crucial for creating the right consistency and quality of the final product.

The third type of rubber processing machine is the extruder. Extruders are used to form rubber into various shapes and sizes. They can be used to create sheets, tubes, and other shapes, which are then further processed to produce finished products.

Finally, there are the compression molding machines. These machines are used to shape rubber into desired products, such as toys, automotive parts, and packaging materials. Compression molding is a fast and efficient method for producing large quantities of uniformly shaped rubber products.

1. Rubber Processing Machines

2. Vulcanization Machine

3. Mixing Machine

4. Extruder

5. Compression Molding Machine

This article provides an in-depth overview of the various types of rubber processing machines used in the rubber industry. From vulcanization machines to compression molding machines, each machine plays a crucial role in transforming raw materials into high-quality rubber products. By understanding the different types of rubber processing machines, readers can better appreciate the importance of these machines in the rubber industry and how they contribute to the development of innovative products.