The Role of the Mixer in the Manufacturing Process

The mixer is an essential piece of machinery in the manufacturing industry, used to combine and blend materials. It plays a crucial role in the production process by ensuring that the ingredients are thoroughly mixed and combined to form a uniform mixture. The mixer is designed to handle a wide range of materials, including powders, liquids, and solids, and can be used in various industries such as food processing, pharmaceuticals, and chemical engineering.

One of the main functions of the mixer is to homogenize the mixture. This means that all parts of the mixture are evenly distributed, resulting in a more consistent product. The mixer also helps to break down any lumps or clumps in the mixture, making it easier to pour and distribute throughout the final product.

Another important aspect of the mixer is its ability to heat and cool the mixture. This is particularly useful in the food industry, where the temperature of the mixture can affect the quality and texture of the final product. The mixer can be equipped with heating and cooling systems to control the temperature of the mixture during the mixing process.

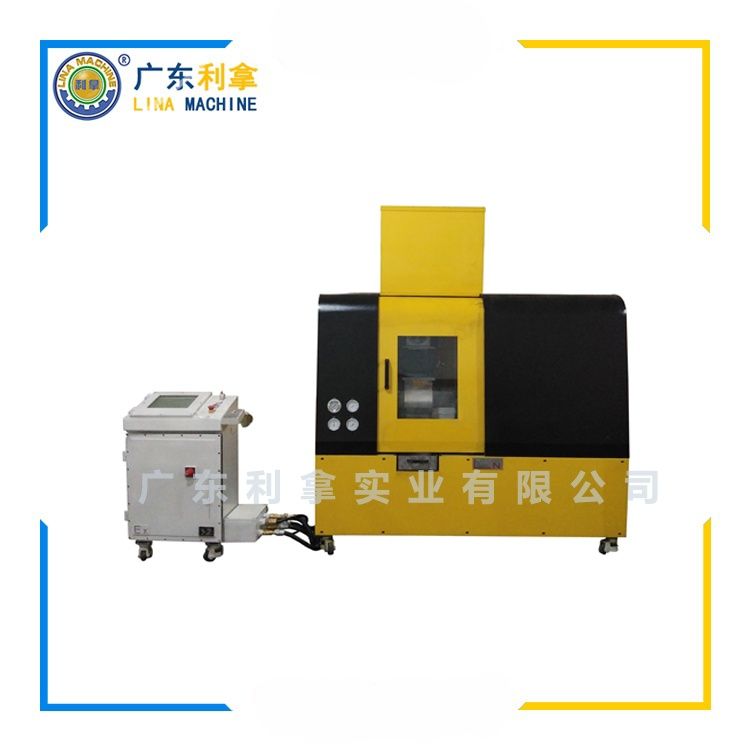

In addition to its technical functions, the mixer is also aesthetically pleasing. Many modern mixers come in sleek and modern designs, which not only improves efficiency but also adds to the overall appearance of the manufacturing facility.

1. Mixer

2. Manufacturing Process

3. Homogenization

4. Heat and Cool System

5. Aesthetic Appeal

This article provides an in-depth overview of the role of the mixer in the manufacturing process, highlighting its importance in achieving a uniform mixture and breaking down lumps. The mixer's ability to homogenize and heat/cool the mixture is discussed, along with its aesthetic appeal. By understanding the key functions of the mixer, manufacturers can optimize their processes and produce high-quality products.