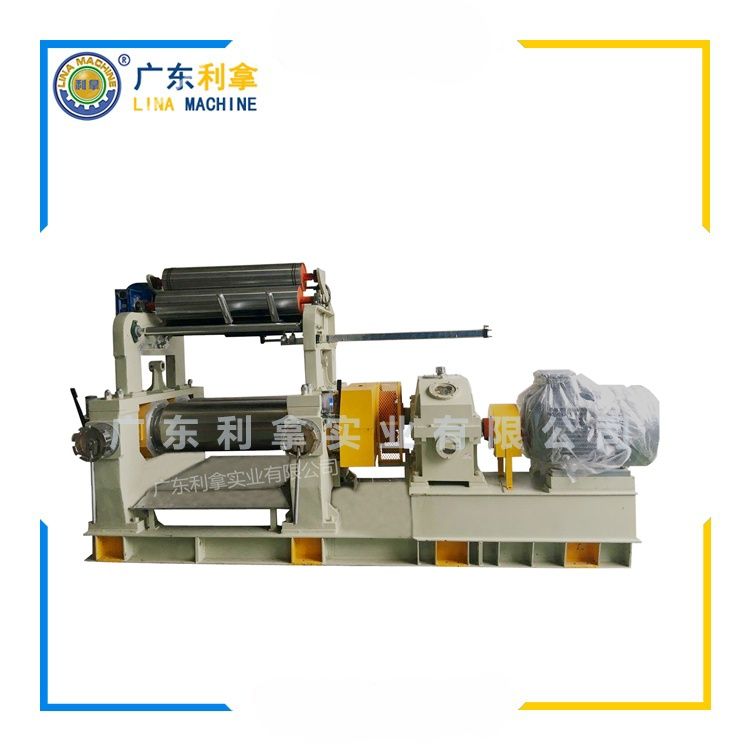

The Four-Roll Mill - A Revolutionary Tool for Rubber and Plastics Manufacturing

The four-roll mill, also known as a four-roll extruder, is an essential tool in the production of rubber and plastic products. It is a versatile machine that can be used to process a wide range of materials, including natural and synthetic rubbers, thermoplastics, and elastomers. In this article, we will explore the features, advantages, and applications of this innovative machine.

Features of the Four-Roll Mill:

1. Variable Speed Control: The four-roll mill comes with a variable speed control system that allows for precise adjustment of the feeding rate and extrusion speed. This ensures that the material is processed at the optimal temperature and pressure required for the desired product properties.

2. High-Quality Extrusion: The four-roll mill has a high-quality extruder head that produces smooth and evenly distributed material. This helps to minimize air inclusions and improve the overall quality of the product.

3. Easy Maintenance: The four-roll mill is designed to be easy to maintain and operate. Its compact size and simple design make it ideal for small-scale operations or those with limited space.

4. Versatile Applications: The four-roll mill is suitable for a wide range of applications, including but not limited to:

- Rubber processing: It can be used to process natural and synthetic rubbers, including latex, nitrile, and polyurethane.

- Plastic processing: It can be used to process thermoplastics such as ABS, HDPE, and PP.

- Elastomer processing: It can be used to process elastomers such as silicone and neoprene.

Advantages of the Four-Roll Mill:

1. Cost-Effectiveness: Compared to other processing methods, the four-roll mill is more cost-effective. It requires less energy and produces fewer waste materials, making it a greener option for many manufacturers.

2. Product Quality: The four-roll mill produces high-quality products that meet industry standards. Its ability to produce smooth and evenly distributed material helps to minimize air inclusions and improve the overall quality of the product.

3. Convenience: The four-roll mill is easy to use and maintain. Its compact size and simple design make it ideal for small-scale operations or those with limited space.

Applications of the Four-Roll Mill:

The four-roll mill is widely used in the manufacturing of various products, including but not limited to:

- Rubber products: It is used to produce tires, hoses, gloves, and other rubber products.

- Plastic products: It is used to produce toys, packaging materials, and other plastic products.

- Elastomer products: It is used to produce silicone products, such as silicone belts and seals.

1. Four-Roll Mill

2. Rubber Processing

3. Plastic Processing

4. Elastomer Processing

5. Green Manufacturing

The four-roll mill is a revolutionary tool for rubber and plastic manufacturing that offers cost-effectiveness, high-quality products, and convenience. With its variable speed control, high-quality extruder head, and versatile applications, it is ideal for small-scale operations or those with limited space. Whether you are producing rubber products, plastic products, or elastomer products, the four-roll mill is your go-to solution for efficient and effective processing. Its green manufacturing capabilities make it an environmentally friendly option for many manufacturers.