Flexible Plastic Pellet Production Line

The flexible plastic pellet production line is a crucial component in the manufacturing industry, particularly in the plastics and rubber sectors. This article will provide an overview of the key components of this line, their functions, and how they work together to produce high-quality plastic pellets efficiently.

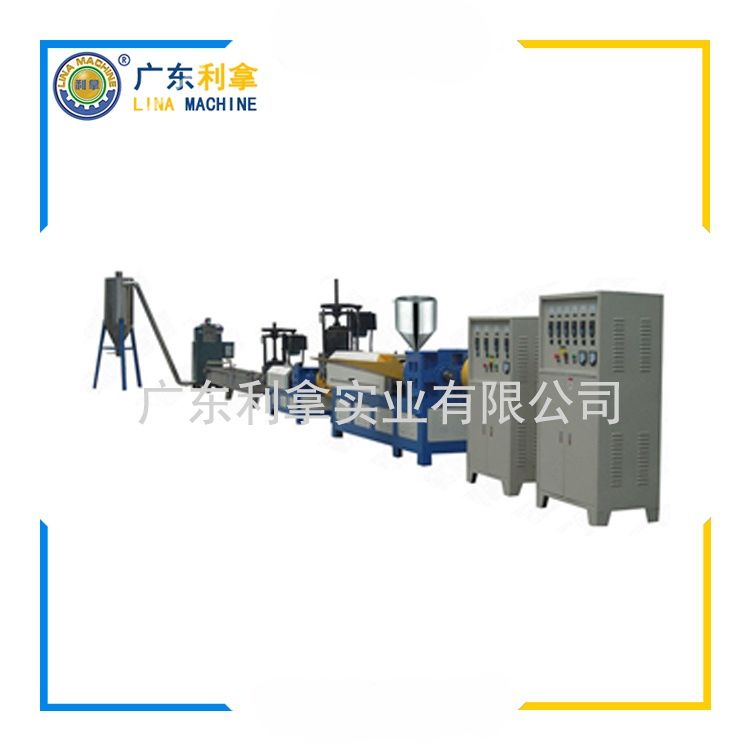

At the heart of the flexible plastic pellet production line is the extruder. This machine uses heat and pressure to convert raw materials into a uniform, granular form. The extruder's ability to control the temperature and pressure is critical to producing consistent pellets with a consistent size and shape.

Next, the pellets are cooled and granulated by a granulator. This process removes any excess moisture or impurities from the pellets, ensuring that they meet quality standards. The granulator's design and efficiency play a significant role in the final product's consistency and quality.

After granulation, the pellets are dried and sorted through a series of screening and sorting machines. These machines help to remove any remaining impurities and ensure that the pellets meet specific quality standards before being packaged and shipped.

Finally, the finished plastic pellets are packaged and stored for future use. The packaging process must be efficient and cost-effective, while also protecting the pellets from damage during transportation and storage.

1. Flexible Plastic Pellet Production Line

2. Extruder

3. Granulator

4. Screening Machine

5. Quality Standards

6. Packaging Process

7. Efficiency

8. Cost-Effectiveness

9. Transportation and Storage Protection

This article provides an in-depth analysis of the key components and processes involved in the flexible plastic pellet production line. By highlighting the importance of each component and their role in the overall process, we aim to help readers understand how these machines work together to produce high-quality plastic pellets efficiently. The focus on quality standards, packaging efficiency, and cost-effectiveness ensures that our readers have all the information they need to make informed decisions about investing in this valuable technology.