The Role of Hydraulic Flip-Furnace in the Manufacturing Industry

The manufacturing industry is a complex and dynamic sector that relies heavily on advanced machinery to meet its production needs. One such machine is the hydraulic flip-furnace, which plays a crucial role in the process of plastic compounding. In this article, we will explore the functions, benefits, and applications of hydraulic flip-furnaces in the manufacturing industry.

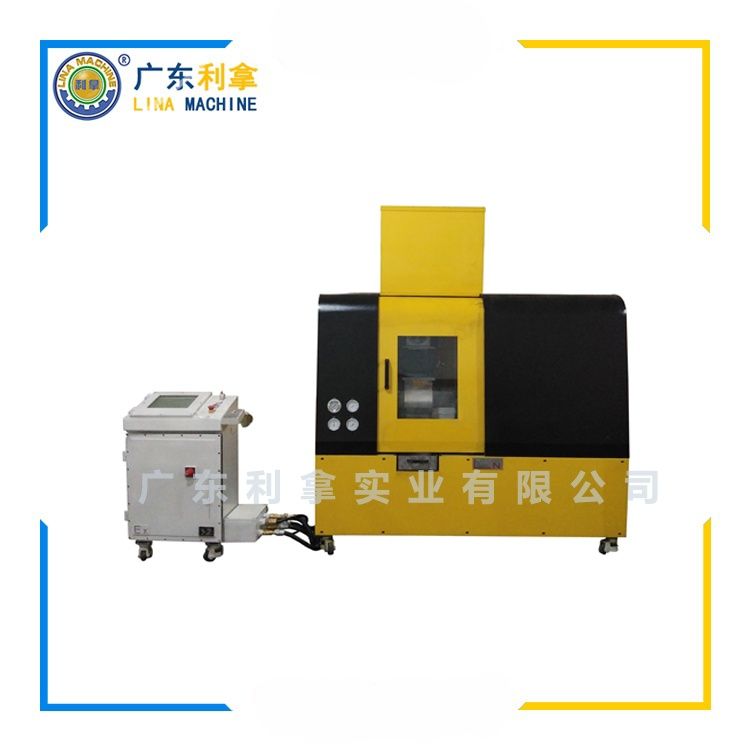

Firstly, let's understand what a hydraulic flip-furnace is. It is a specialized type of mixer used in the plastics industry for compounding and mixing raw materials into a homogeneous mixture. Unlike traditional mixers, hydraulic flip-furnaces use hydraulic power to rotate the barrel, allowing for more precise control over the mixing process. This results in a higher degree of uniformity and consistency in the final product.

One of the main advantages of hydraulic flip-furnaces is their ability to handle a wide range of materials. They are designed to work with a variety of plastics, including polyethylene, polypropylene, and other thermoplastics. This makes them ideal for industries that require a consistent and reliable supply of plastic products.

Another significant benefit of hydraulic flip-furnaces is their efficiency. Compared to traditional mixers, they can produce more material per hour, resulting in faster production times. This not only saves time but also reduces costs associated with manual labor and equipment maintenance.

In addition to their practical benefits, hydraulic flip-furnaces also have aesthetic advantages. They are often designed to match the aesthetics of the surrounding environment, making them an attractive addition to any manufacturing facility.

Finally, hydraulic flip-furnaces are highly adaptable to different production requirements. They can be customized to suit specific needs, such as temperature control or speed adjustment, making them a versatile tool for various industrial processes.