Precision Roller Press for Sheet Metal

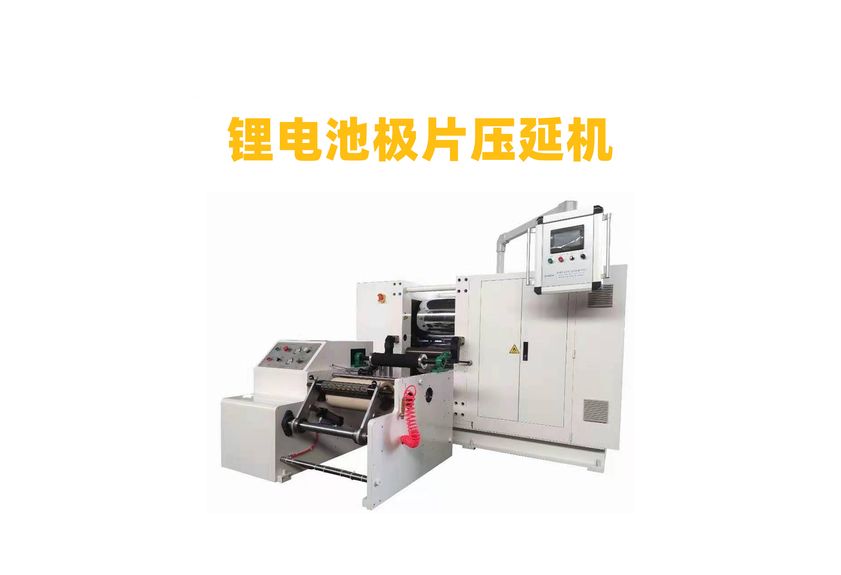

The precision roller press is a crucial tool in the manufacturing industry, specifically in the sheet metal processing sector. This machine is designed to produce high-quality sheets of metal with minimal defects and irregularities. The roller press consists of several components, including the main roller assembly, the guide rollers, and the pressure rollers. The main roller assembly is responsible for applying pressure to the material as it passes through the rollers. The guide rollers are used to guide the material as it moves through the press. The pressure rollers exert force on the material, causing it to be compressed and deformed.

One of the key features of the precision roller press is its ability to precisely control the amount of pressure applied to the material. This is achieved through the use of hydraulic or pneumatic cylinders that can be adjusted to achieve the desired force level. Another important aspect of the roller press is its ability to handle different types of materials, including steel, aluminum, and copper. The machine is equipped with various tools and accessories that allow it to perform a wide range of operations, such as bending, rolling, and shaping.

In addition to its technical capabilities, the precision roller press is also highly efficient and cost-effective. It reduces waste by minimizing the amount of material that is wasted during the process. This is particularly important in industries where raw materials are expensive and must be used efficiently. The precision roller press also has a low maintenance requirement, making it an attractive option for businesses looking to reduce their operating costs.