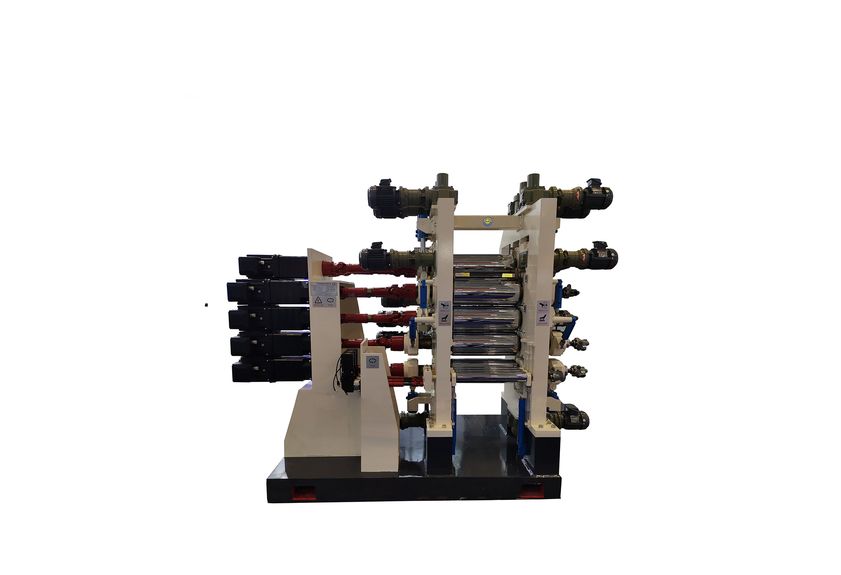

PCM相变化导热硅胶压延机:创新技术在材料加工领域的应用

In the realm of advanced materials processing, innovation is not just a buzzword. It's a necessity for companies to stay competitive in today's fiercely competitive market. One such innovative tool that has taken the industry by storm is the PCM phase change thermal conductive silicone roller press. This machine is designed to process and shape silicone sheets into precise shapes, ensuring optimal performance in various applications.

The PCM phase change thermal conductive silicone roller press is a game-changer in the manufacturing industry. Its unique features make it stand out from traditional machines. For instance, its ability to handle different types of silicone sheets without compromising their quality or performance is unparalleled. The machine's precision control system ensures that each sheet is precisely cut and shaped, resulting in consistent output every time.

One of the most significant advantages of this machine is its efficiency. It can process multiple sheets at once, reducing downtime and increasing productivity. Additionally, its compact design makes it easy to move around the factory floor, making it ideal for small and medium-sized businesses.

Another notable feature of the PCM phase change thermal conductive silicone roller press is its ability to adapt to changing market demands. With its flexible operating parameters, it can easily be customized to meet specific requirements, whether it's for high-end electronics or low-cost consumer goods.

In conclusion, the PCM phase change thermal conductive silicone roller press is a game-changer in the manufacturing industry. Its innovative features, efficiency, and flexibility make it an essential tool for any company looking to improve their production processes. As technology continues to advance, we can expect more and more innovative tools like this one to emerge, further revolutionizing the way we manufacture and produce materials.