Understanding the Low-Temperature Rubber Filter Press

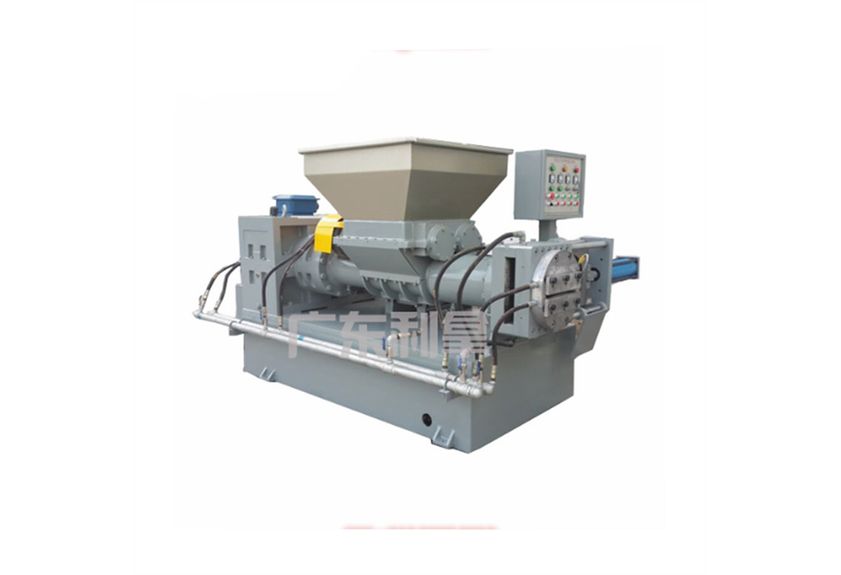

The low-temperature rubber filter press is a crucial tool in the manufacturing industry, particularly in the pharmaceutical and food processing sectors. This machine is designed to efficiently filter out impurities from liquids at extremely low temperatures, ensuring that the final product meets high quality standards. The process involves using a rubber filter element that is specifically designed for handling cold liquids, which helps to prevent any damage or degradation to the product during filtration.

One of the key features of this type of filter press is its ability to operate at very low temperatures, which makes it ideal for separating out particles from liquids that would otherwise be too hot to handle. This technology is particularly useful in applications where temperature control is critical, such as in the production of vaccines or certain types of pharmaceuticals.

Another important aspect of the low-temperature rubber filter press is its efficiency. Thanks to the use of specialized filters and advanced filtration techniques, this machine can produce high-quality products with minimal waste. This not only saves time and resources but also reduces costs associated with contaminated or unusable materials.

In addition to its technical advantages, the low-temperature rubber filter press also has a significant impact on the environment. By reducing the need for heat and energy, this machine helps to minimize greenhouse gas emissions and other pollutants associated with traditional filtration processes. This not only benefits the environment but also contributes to a more sustainable future for industries that rely on these technologies.

1. low-temperature rubber filter press

2. pharmaceutical industry

3. food processing

4. particle separation

5. temperature control

The low-temperature rubber filter press is an essential tool in the pharmaceutical and food processing industries, offering superior filtration capabilities at extremely low temperatures. This innovative technology ensures that products are filtered with minimal waste and produces high-quality results. By leveraging advanced filtration techniques and specialized filters, this machine can help reduce greenhouse gas emissions and other pollutants associated with traditional filtration processes. With its unique combination of efficiency and environmental benefits, the low-temperature rubber filter press is poised to become a game-changer in the world of manufacturing.