The Role of the Two-Roll Rolling Mill in Metal Forming

The two-roll rolling mill is a crucial tool in the metal forming industry, used to create various products such as sheet metal, strips, and profiles. This machine uses two rollers to press and deform metal sheets or strips into desired shapes and sizes. It is widely used in industries like automotive, construction, and electrical engineering.

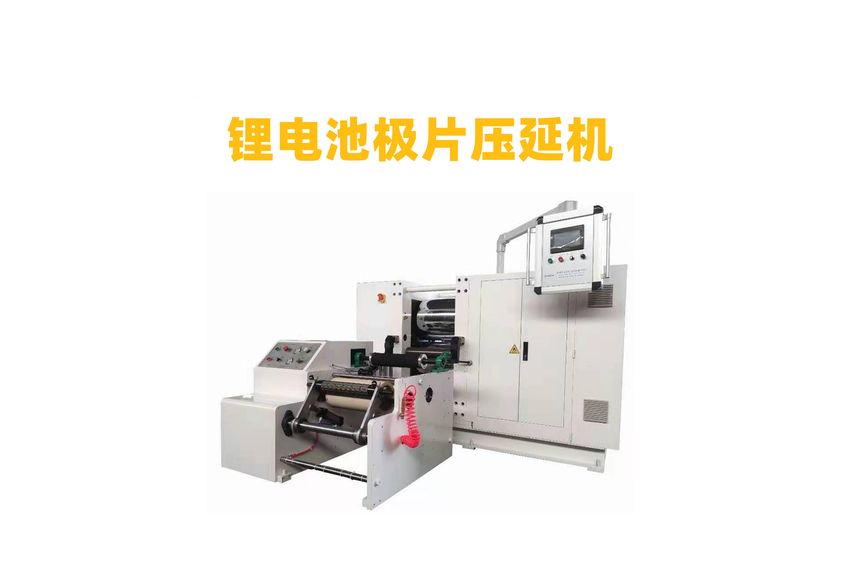

The two-roll rolling mill consists of two parallel rollers that are mounted on a frame. These rollers are usually made of high-carbon steel and have a smooth surface to ensure a uniform deformation of the metal. The rollers are arranged with a slight gap between them, which allows for the metal to slide over the rollers during the rolling process.

The two-roll rolling mill operates by applying pressure to the metal using hydraulic cylinders or pneumatic cylinders. This pressure is applied in both directions, causing the metal to be deformed and drawn towards the center of the rollers. The speed of the rollers can be adjusted to control the degree of deformation and the thickness of the formed product.

One of the key advantages of the two-roll rolling mill is its ability to produce high-quality products with minimal waste. The machine has a high precision and accuracy, which ensures that the formed product meets the required specifications. Additionally, it can handle a wide range of materials, including aluminum, steel, and copper, making it a versatile tool for various industries.

In conclusion, the two-roll rolling mill plays a vital role in the metal forming industry by providing a reliable and efficient way to produce various products. Its ability to produce high-quality products with minimal waste makes it an essential tool for any manufacturing facility.