The Role of Thermal Dissipation Graphite Film Rolling Machine in the Manufacturing Industry

The manufacturing industry is a complex and ever-evolving field that demands precision, efficiency, and reliability. One crucial component that plays a vital role in this industry is the thermal dissipation graphite film rolling machine. This machine is designed to produce high-quality graphite films that are essential for various applications such as electronics, energy storage, and heat management. In this article, we will explore the importance of thermal dissipation graphite film rolling machines in the manufacturing industry and their impact on the overall performance of the production process.

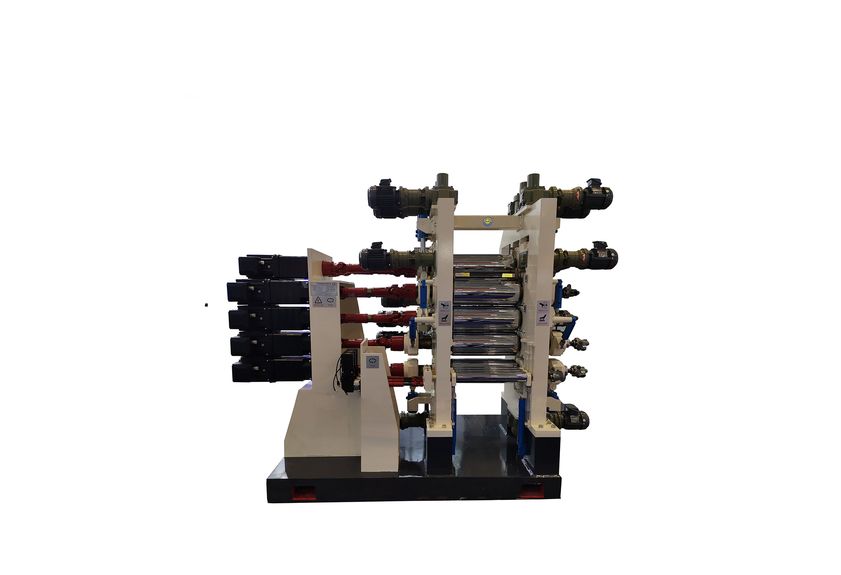

Firstly, let us understand what thermal dissipation graphite film rolling machines are. These machines are specialized equipment used to roll thin sheets of graphite material into a uniform and consistent thickness. The graphite material used in these machines is highly conductive, which means it can quickly dissipate heat generated by electronic components or other machinery. This property makes graphite films ideal for use in applications where heat management is critical, such as in electronics, power generation, and automotive industries.

Now, let us discuss the importance of thermal dissipation graphite film rolling machines in the manufacturing industry. Firstly, they help to reduce the overall cost of production by eliminating the need for expensive cooling systems. Instead of relying on external cooling mechanisms, these machines produce graphite films that have excellent thermal conductivity, allowing them to dissipate heat more efficiently. This results in reduced energy consumption and lower maintenance costs, which ultimately leads to cost savings for the manufacturing company.

Secondly, thermal dissipation graphite film rolling machines improve product quality and reliability. By using these machines, manufacturers can produce graphite films with consistent thickness and smooth surface finishes. This ensures that the final product meets the required specifications and performs optimally under different operating conditions. As a result, customers receive products that are reliable, durable, and meet their needs.

Thirdly, thermal dissipation graphite film rolling machines contribute to environmental sustainability by reducing the need for cooling systems. By using these machines, manufacturers can eliminate the use of expensive cooling systems that consume a significant amount of energy. This reduces greenhouse gas emissions and helps to conserve resources, making the manufacturing process more sustainable.

Finally, thermal dissipation graphite film rolling machines enhance product customization and flexibility. With the ability to produce graphite films of different thicknesses and surface finishes, manufacturers can customize their products to meet specific customer requirements. This allows them to offer a wider range of products and increase their market share.

In conclusion, thermal dissipation graphite film rolling machines play a crucial role in the manufacturing industry by improving product quality, reducing costs, enhancing sustainability, and increasing flexibility. As technology continues to advance, it is likely that these machines will become even more important in the future. Therefore, it is essential for manufacturers to invest in these machines and stay up-to-date with the latest advancements in the industry.