The Role of the Six-Roll Rolling Press in Metal Forming

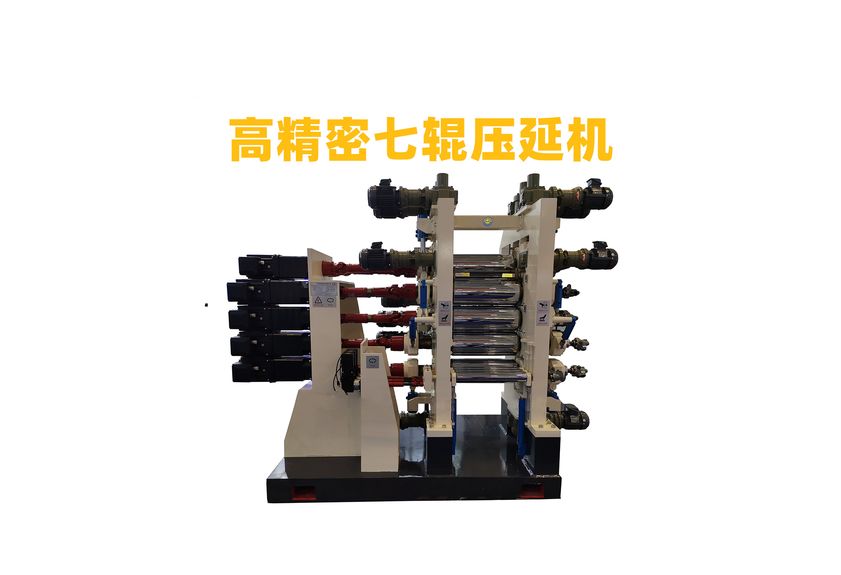

The six-roll rolling press is a crucial tool in the metal forming industry, particularly in the production of sheet metal products. This versatile machine is capable of shaping various materials into sheets, strips, and profiles with precision and efficiency. Its design allows for easy adjustment of the roller pressure, which determines the thickness and quality of the formed product.

One of the key features of the six-roll rolling press is its ability to handle a wide range of materials, including steel, aluminum, and copper. The machine's high-quality rollers ensure that the material is evenly distributed across the surface, resulting in a uniform thickness throughout the sheet. This feature is particularly important when producing sheet metal products with intricate designs or patterns.

In addition to its mechanical advantages, the six-roll rolling press also boasts advanced automation features. These include computerized control systems that allow for precise measurement and monitoring of the process. This technology ensures that the machine operates at optimal efficiency and reduces the risk of human error during the manufacturing process.

The six-roll rolling press is not only used for sheet metal products but also plays a significant role in other industries such as automotive, aerospace, and construction. Its versatility makes it an essential tool for businesses looking to produce high-quality products quickly and efficiently.

1. Six-roll rolling press

2. Metal forming

3. Sheet metal products

4. Automotive industry

5. Aerospace industry

6. Construction industry

This article provides an in-depth analysis of the six-roll rolling press, highlighting its importance in the metal forming industry. We discuss its capabilities, applications, and automation features, showcasing its versatility and efficiency in various industries. By understanding the benefits of this versatile machine, businesses can make informed decisions about their manufacturing processes.