The Role of Open Roller Mills in Shoe Material Production

Open roller mills are an essential tool in the shoe material production industry. They play a crucial role in the process of mixing, kneading, and shaping various materials used in the manufacture of shoes. These machines are designed to handle a wide range of materials, including leather, synthetic fibers, and other textiles, and they can be used to create a variety of shoe components such as soles, uppers, and laces.

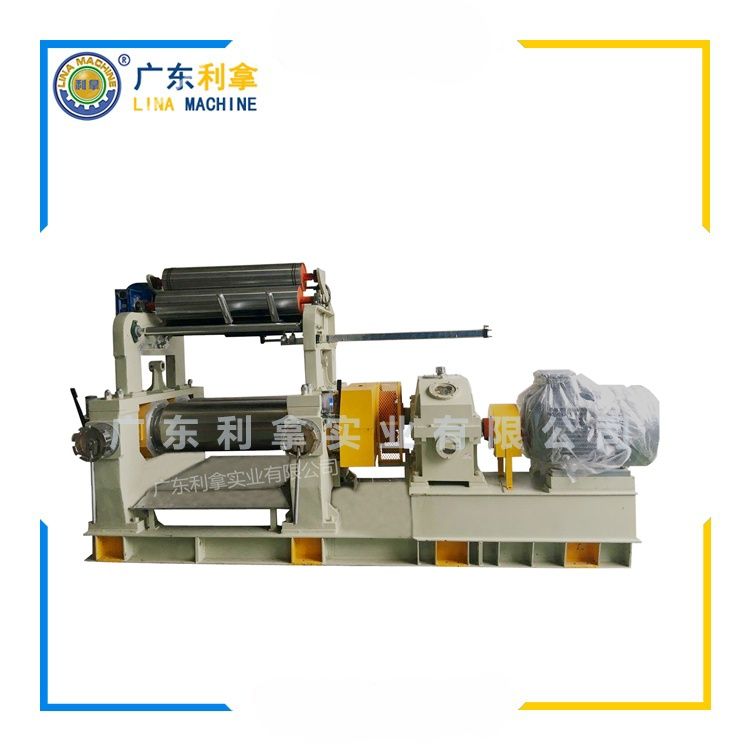

The open roller mill is a complex machine that consists of several parts, including the rollers, motor, control system, and cooling system. The rollers are responsible for the mixing and kneading of the materials, while the motor drives them at high speeds. The control system monitors the progress of the process and adjusts the speed and pressure of the rollers as needed. The cooling system helps to prevent overheating and maintain the consistency of the materials being processed.

One of the key benefits of using open roller mills is their ability to produce high-quality products with minimal waste. By controlling the temperature and pressure of the materials being processed, these machines can produce uniformly shaped and textured components that meet the exact specifications of the end product. This not only saves time and resources but also improves the overall quality of the finished product.

In addition to their technical advantages, open roller mills also have a significant impact on the environment. By reducing waste and minimizing energy consumption, these machines help to reduce greenhouse gas emissions and contribute to a more sustainable future. As demand for eco-friendly products continues to grow, manufacturers are increasingly turning to open roller mills as a cost-effective solution that meets both economic and environmental goals.

1. Shoe Material Production

2. Open Roller Mill

3. Mixing and Kneading

4. High Quality Products

5. Environmental Sustainability

This article provides an in-depth analysis of the importance of open roller mills in the production of shoe materials. It discusses how these machines enable efficient mixing and shaping of various materials, resulting in high-quality products with minimal waste. Additionally, it highlights the environmental benefits of using open roller mills, which contribute to a more sustainable future. By understanding the capabilities and advantages of open roller mills, manufacturers can make informed decisions about their production processes and align with current trends towards sustainability and efficiency.