The Seven-Roller Rolling Press: A Detailed Guide to Its Functions and Applications

The seven-roller rolling press is a versatile manufacturing tool that has been used for decades in various industries. This machine is designed to perform a wide range of operations, including shaping, drawing, and extrusion. In this article, we will explore the functions of a seven-roller rolling press, its applications, and some tips for using it effectively.

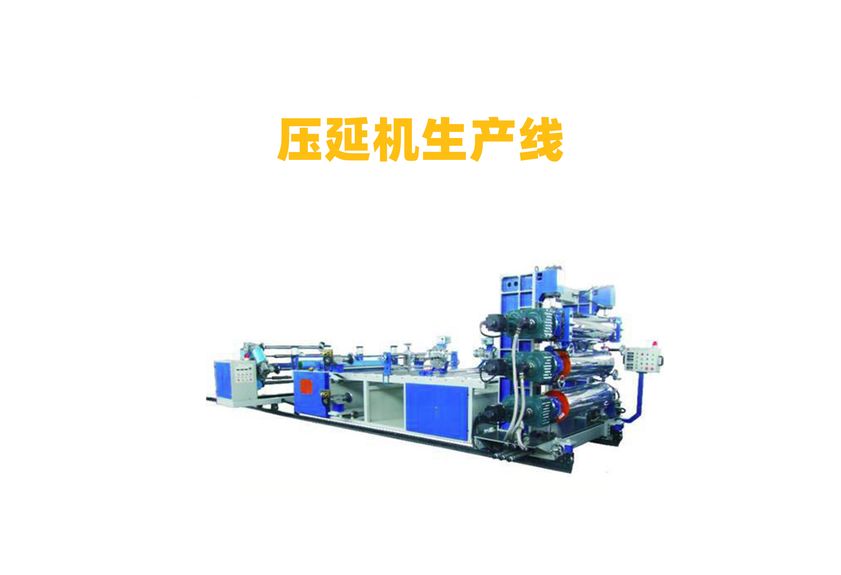

Firstly, let's understand what a seven-roller rolling press is. It is a type of press that uses seven rollers to apply pressure and shape materials. These rollers are arranged in a specific pattern, which allows the material to be deformed or formed into desired shapes. The seven-roller rolling press is commonly used in the automotive, aerospace, and electronics industries, where it is essential for producing parts with precision and accuracy.

One of the key functions of a seven-roller rolling press is its ability to handle a wide range of materials. This includes metals, plastics, and composites. The press can be customized to suit the specific requirements of each material, ensuring that the part produced meets the required standards. Additionally, the press is capable of performing complex operations such as bending, drawing, and extrusion, which are crucial for many industrial applications.

In terms of applications, the seven-roller rolling press is widely used in the automotive industry for producing parts like engines, transmissions, and suspension systems. In the aerospace industry, it is used to produce components like wings, fuselages, and engines. In the electronics industry, it is used to produce circuit boards, connectors, and other electronic components.

To use a seven-roller rolling press effectively, there are several tips that you should keep in mind. Firstly, it is important to understand the specific requirements of the material being processed. This will help you select the appropriate roller configuration and operating parameters to ensure optimal results. Secondly, proper maintenance is crucial for maintaining the longevity of the press. This includes regular cleaning and lubrication of the rollers and other moving parts. Thirdly, safety measures should always be taken when using the press. This includes wearing personal protective equipment and following all safety guidelines.

In conclusion, the seven-roller rolling press is a versatile tool that has been used in various industries for decades. Its ability to handle a wide range of materials and perform complex operations makes it an essential piece of machinery for many industries. By understanding its functions and applying proper maintenance practices, you can ensure that your seven-roller rolling press is working efficiently and effectively.