The Role of Talc Powder Granulators in the Manufacturing Industry

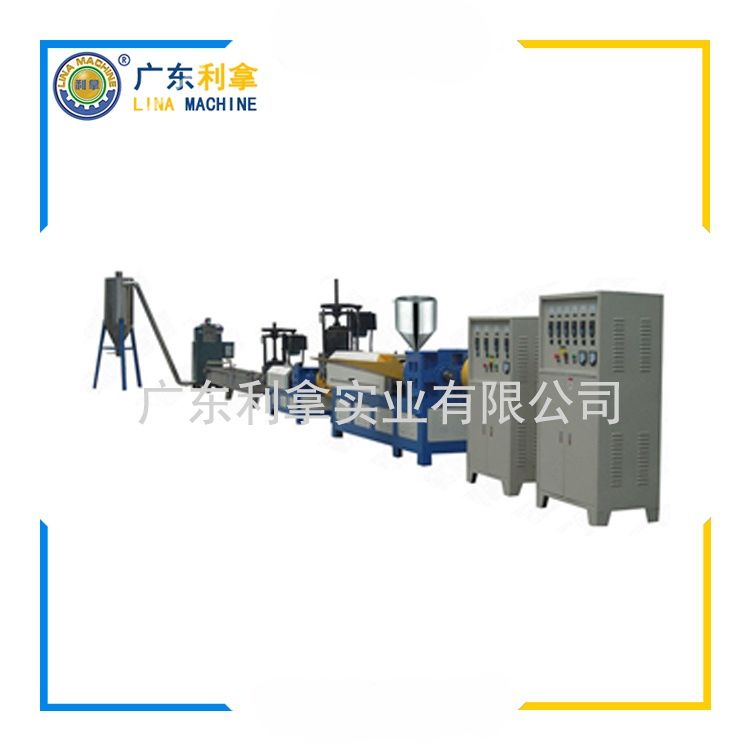

Talc powder granulators are essential tools in the manufacturing industry, particularly in the production of various types of products that require a fine and consistent texture. These machines play a crucial role in transforming raw materials into high-quality talc powder, which is then used as a filler or reinforcement in various industrial applications. In this article, we will explore the different types of talc powder granulators, their functions, and how they contribute to the overall process of product manufacturing.

Firstly, there are two main types of talc powder granulators: rotary granulators and fluidized bed granulators. Rotary granulators use a rotating drum to crush and grind the talc material, while fluidized bed granulators use a fluidized bed of air to break down the talc particles. Both types of granulators have their advantages and disadvantages, but they work together to produce a high-quality talc powder.

Rotary granulators are typically used for larger-scale production, with a capacity ranging from several tons to hundreds of tons per hour. They are designed to handle a wide range of talc materials, including natural talc, synthetic talc, and other minerals. The rotating drum rotates at high speeds, causing the talc material to be crushed and ground, resulting in a uniform and fine powder. This type of granulator is ideal for large-scale production, as it can quickly turn over large batches of talc material.

Fluidized bed granulators, on the other hand, are designed for smaller-scale production, with capacities ranging from a few hundred grams to several tons per hour. These granulators use a fluidized bed of air to break down the talc particles, producing a more uniform and fine powder. Fluidized bed granulators are ideal for small-scale production, as they can handle a limited amount of talc material without compromising the quality of the powder.

In addition to their function in the manufacturing process, talc powder granulators also play a critical role in environmental sustainability. By using these machines, manufacturers can reduce waste and minimize the amount of energy required to produce talc powder. This not only helps to conserve resources but also reduces the environmental impact of the manufacturing process.

In conclusion, talc powder granulators are essential tools in the manufacturing industry, particularly in the production of high-quality talc powder. There are two main types of granulators: rotary granulators and fluidized bed granulators, each with their own advantages and disadvantages. By using these machines, manufacturers can produce a high-quality talc powder while reducing waste and minimizing the environmental impact of the manufacturing process.