Understanding the Single-Screw Extrusion Spinneret

In the realm of polymer processing, the single-screw extruder is a cornerstone in the production of thermoplastic pellets. This versatile machine operates by forcing molten plastic through a series of interlocking metal screws that shape the material into pellets. The process is highly efficient and can produce pellets with consistent quality and size, making it an essential tool for many industrial applications.

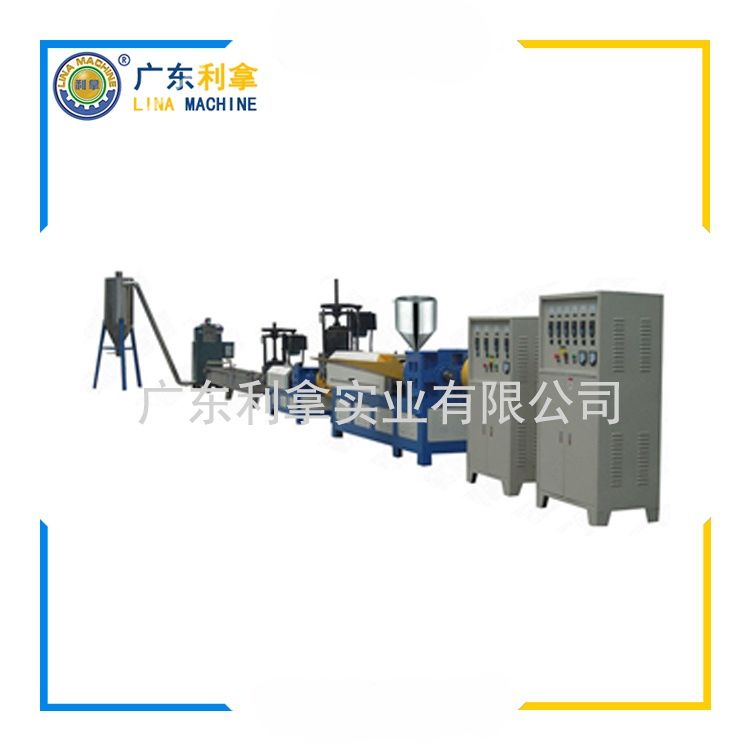

The single-screw extruder's design is characterized by its simple yet robust structure. It consists of a barrel, which holds the molten plastic, and a spindle, which rotates the screws. The barrel is typically made from high-density polyethylene (HDPE) or other heat-resistant materials to ensure longevity and minimize wear and tear. The spindle is driven by a motor, which powers the screws and allows them to move at high speeds.

The single-screw extruder's primary function is to convert molten plastic into pellets. The process begins with the feedstock entering the barrel, where it is heated to the appropriate temperature for extrusion. As the plastic moves down the barrel, it encounters the rotating screws, which force it through a series of compression and elongation steps. This process results in the formation of a uniformly shaped pellet, which exits the extruder at the die.

One of the key advantages of the single-screw extruder is its ability to produce pellets of consistent size and shape. This is achieved through precise control of the screw speed and the pressure applied to the molten plastic. By adjusting these parameters, operators can tailor the final product's properties, such as density, strength, and flexibility.

Another benefit of this machine is its flexibility in terms of material selection. Single-screw extruders are capable of processing a wide range of thermoplastics, including polyolefins, polyamides, and polyesters. This makes them ideal for producing a variety of products, from packaging materials to medical devices.

In conclusion, the single-screw extruder is a powerful tool in the world of polymer processing. Its ability to produce pellets of consistent quality and size, along with its versatility in material selection, make it an essential piece of equipment for any industry looking to improve their production efficiency and quality.