Understanding the EVA, TPR, and PVC Compounding Production Lines

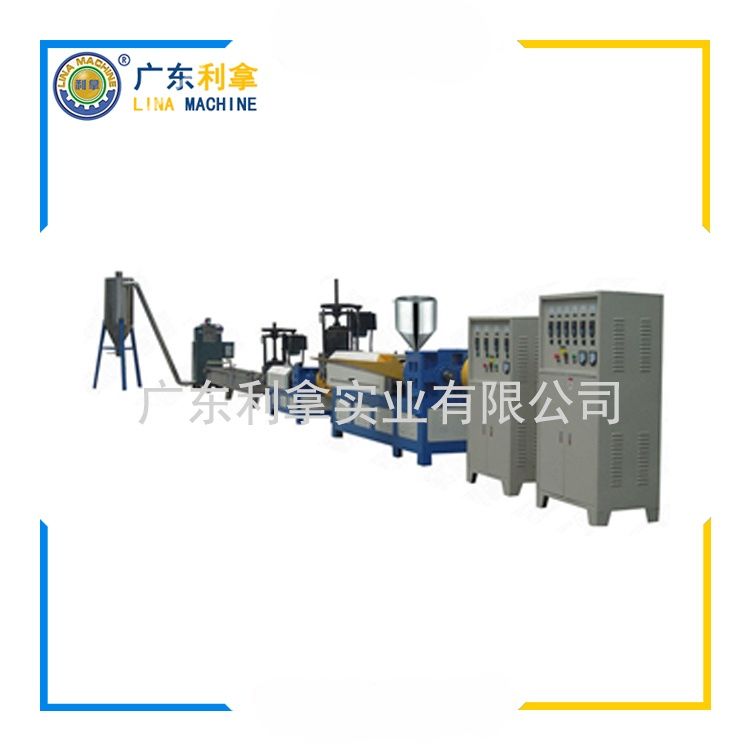

The compounding production line is an essential part of the plastics manufacturing process. It involves the mixing of various raw materials to create a uniform compound that can be used in various applications. In this article, we will explore the three main types of compounding production lines - EVA (Ethylene Vinyl Acetate), TPR (Thermoplastic Rubber), and PVC (Polyvinyl Chloride) - and their respective features and applications.

1. EVA Compounding Production Line:

EVA is a thermoplastic elastomer that is widely used in a variety of applications such as packaging, automotive, and construction. The EVA compounding production line is designed to produce high-quality EVA compounds that meet specific requirements for each application. This line includes equipment such as extruders, mixers, and granulators that work together to ensure consistency and quality in the final product.

2. TPR Compounding Production Line:

TPR is a thermoplastic rubber that is commonly used in automotive parts, electrical wiring, and other industrial applications. The TPR compounding production line is designed to produce TPR compounds with high strength and flexibility. This line includes equipment such as screw extruders, injection molding machines, and heat presses that work together to produce high-quality TPR products.

3. PVC Compounding Production Line:

PVC is a versatile plastic material that is used in a wide range of applications such as building materials, toys, and packaging. The PVC compounding production line is designed to produce PVC compounds with high clarity and color stability. This line includes equipment such as screw extruders, calenders, and blow molders that work together to produce high-quality PVC products.

1. EVA Compounding Production Line

2. TPR Compounding Production Line

3. PVC Compounding Production Line

4. Plastic Compounding Production Line

5. Automotive Parts

6. Electrical Wiring

7. Industrial Applications

8. High-Quality Products

9. Clear PVC Compounds

10. Color Stability

11. Blow Molding Machines

12. Screw Extruders

13. Calenders

14. Building Materials

15. Toys

16. Packaging

17. Plastic Manufacturing Process

18. Plastic Materials

19. Polyvinyl Chloride (PVC)

20. Thermoplastic Rubber (TPR)

21. Thermoplastic Elastomer (EVA)

The compounding production line plays a crucial role in the plastics manufacturing industry by producing high-quality compounds for various applications. The EVA, TPR, and PVC compounding production lines are specifically designed to meet the needs of these materials, ensuring consistency and quality in the final products. These lines include advanced equipment such as screw extruders, mixers, granulators, and blow molders that work together to produce high-performance compounds. By utilizing these production lines, manufacturers can produce products with superior clarity, color stability, and other desired properties, which helps them stand out in the competitive market.