The Double Roll Mill: A Detailed Guide to Its Operation and Applications

The double roll mill, also known as a twin-roll mill, is a crucial piece of equipment in the rubber and plastic industry. It is used for mixing, kneading, and extruding materials such as natural and synthetic rubbers, thermoplastics, and elastomers. In this article, we will delve into the operation of a double roll mill, its advantages, and its applications.

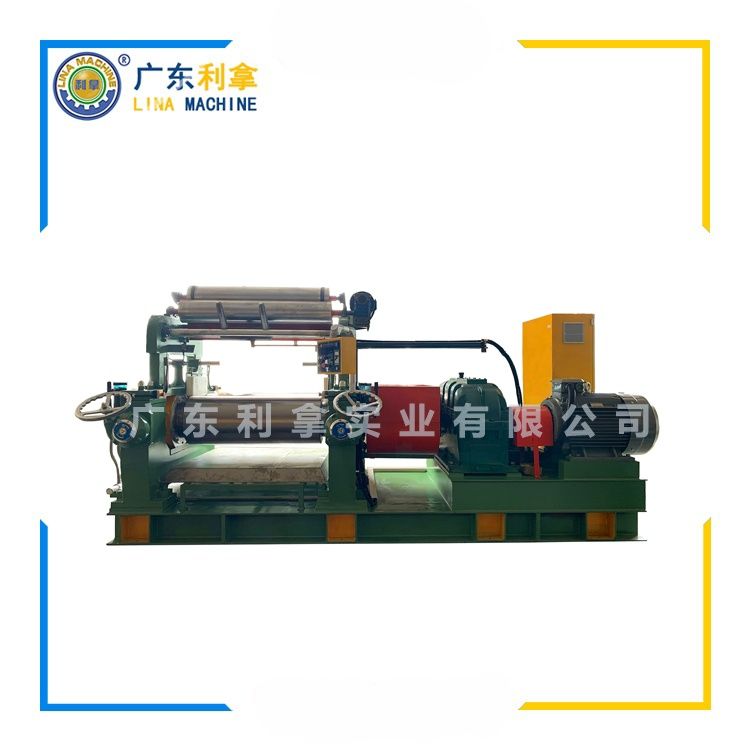

The basic principle behind the operation of a double roll mill is that two rollers rotate at different speeds, causing the material to be forced between them. This force is responsible for breaking down the larger molecules into smaller ones, which are then mixed and shaped into desired products. The rollers are usually made of high-carbon steel or stainless steel, and they are coated with a lubricant to ensure smooth operation.

One of the key advantages of using a double roll mill is its ability to process a wide range of materials. Unlike other types of mixers, it can handle both viscous and non-viscous materials, making it ideal for producing various types of products. Additionally, the double roll mill's consistent output and precise control over the mixing process make it an efficient tool for industrial production.

In terms of applications, the double roll mill is widely used in the rubber and plastic industry. It is used to produce tires, hoses, gloves, and many other consumer goods. Additionally, it is also used in the automotive industry for manufacturing brake pads, seals, and other components. Furthermore, the mill is employed in the food industry for processing ingredients such as flour, sugar, and starch.

To operate a double roll mill effectively, it is essential to understand its components and how they work together. The rollers rotate at different speeds, causing the material to be forced between them. This force is responsible for breaking down the larger molecules into smaller ones, which are then mixed and shaped into desired products. The rollers are usually made of high-carbon steel or stainless steel, and they are coated with a lubricant to ensure smooth operation.

In conclusion, the double roll mill is a versatile tool that plays a significant role in the rubber and plastic industry. Its ability to process a wide range of materials and its consistent output make it an efficient tool for industrial production. By understanding its operation and application, one can harness its full potential and achieve maximum efficiency in their production processes.