The Metal Mixing Machine: An Essential Tool for the Manufacturing Industry

Metal mixing machines are an indispensable tool in the manufacturing industry, providing a powerful and efficient way to mix metal powders, alloys, and other materials. These machines are designed to handle a wide range of materials, including aluminum, copper, steel, and other metals, and can be used for various applications such as coatings, electronics, and automotive industries.

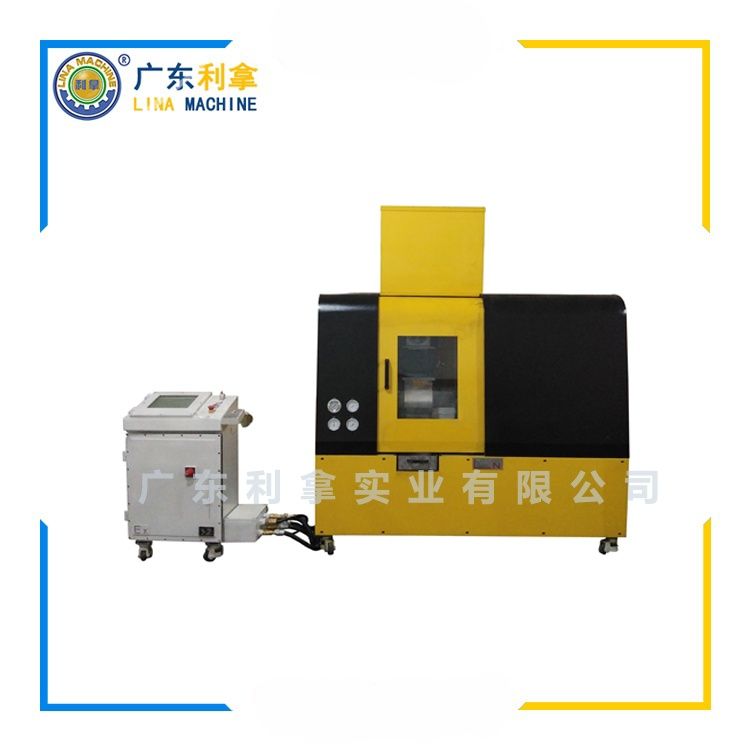

The metal mixing machine consists of a rotating drum that is filled with the material to be mixed. The drum is then rotated at high speeds, causing the material to be forced together and mixed evenly. This process is known as "blending," and it helps to achieve a uniform distribution of the ingredients throughout the mixture.

One of the key features of a metal mixing machine is its ability to handle a wide range of materials, including different types of metals and alloys. This makes it ideal for producing customized products that meet specific requirements, such as high-strength alloys or specialized coatings. Additionally, these machines are often equipped with advanced sensors and control systems that allow for precise temperature and pressure control, ensuring optimal mixing conditions.

In addition to their technical advantages, metal mixing machines also have a significant impact on the environment. By reducing the need for manual labor and minimizing waste, these machines help to reduce energy consumption and greenhouse gas emissions. Furthermore, they can be used to produce materials that are more sustainable and eco-friendly, making them an important part of the green manufacturing movement.

Overall, the metal mixing machine is a crucial tool for the manufacturing industry, providing efficient and effective ways to mix and blend materials. Its ability to handle a wide range of materials and its environmental benefits make it an essential investment for any industrial operation looking to improve efficiency and sustainability.