Understanding the Benefits of Cadmium Powder-Filled Masterbatch Granulators

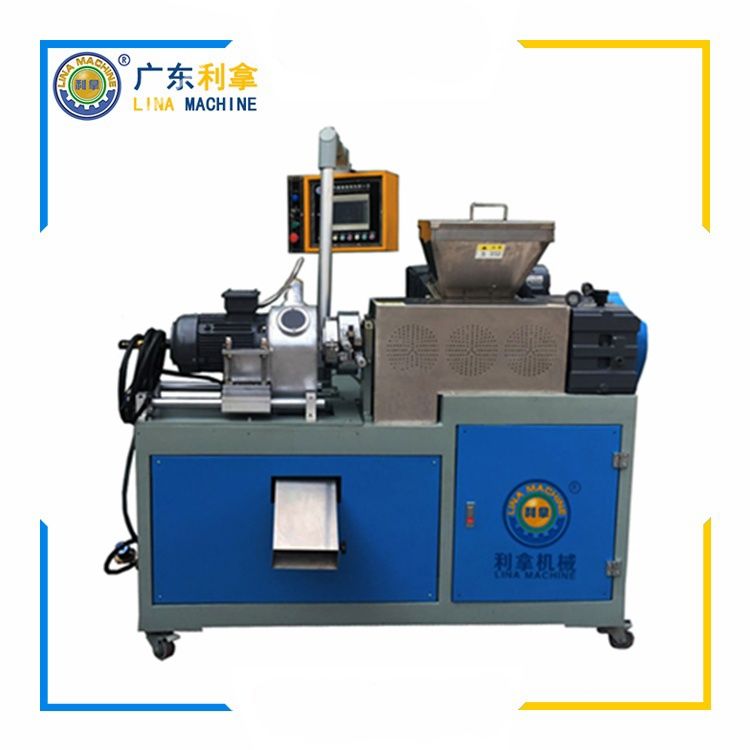

In the realm of polymer processing, masterbatch granulators play a crucial role in enhancing the quality and performance of various plastic products. Among the myriad types of granulators available, those that incorporate calcium powder as a filler have gained significant attention due to their superior properties. This article delves into the benefits of using calcium powder-filled masterbatch granulators, highlighting their significance in the production of high-quality plastic materials.

Firstly, calcium powder-filled masterbatch granulators offer superior flexibility in terms of particle size control. Unlike traditional granulators, these machines allow for precise adjustment of the particle size distribution, ensuring that the final product meets specific requirements. This enhanced flexibility enables manufacturers to tailor their products to meet diverse market demands, thereby increasing customer satisfaction and competitiveness.

Secondly, calcium powder-filled masterbatch granulators contribute to improved process efficiency. By utilizing advanced technology, these machines can reduce downtime and minimize waste during the granulation process. This not only enhances productivity but also reduces operational costs, making them an economical choice for businesses looking to streamline their manufacturing processes.

Thirdly, calcium powder-filled masterbatch granulators enhance the overall quality of the final product. The inclusion of calcium powder not only improves the physical properties of the material but also provides additional protection against environmental factors such as UV radiation and temperature changes. This results in a more durable and reliable product that can withstand harsh conditions without losing its integrity or performance.

Lastly, calcium powder-filled masterbatch granulators promote sustainability and eco-friendliness in the production process. By reducing waste and minimizing energy consumption, these machines help to minimize environmental impact and contribute to a greener future. As consumers become more conscious of their choices, businesses that prioritize sustainability will find themselves at an advantage in the marketplace.

1. Cadmium Powder-Filled Masterbatch Granulators

2. Particle Size Control

3. Process Efficiency

4. Quality Improvement

5. Sustainability

This article explores the benefits of using calcium powder-filled masterbatch granulators in the production of high-quality plastic materials. These innovative machines offer superior flexibility in particle size control, improved process efficiency, enhanced quality, and promote sustainability in the manufacturing process. By understanding the advantages of these granulators, manufacturers can optimize their operations and meet the evolving demands of the market.