The Art of Silver Foil Rolling Machines

The silver foil rolling machine is a sophisticated piece of machinery that has been used for centuries in the manufacturing industry. It is a crucial tool in the production of various products, such as jewelry, electronics, and packaging materials. This article will provide an overview of the different types of silver foil rolling machines, their applications, and some tips for maintaining them.

Types of Silver Foil Rolling Machines:

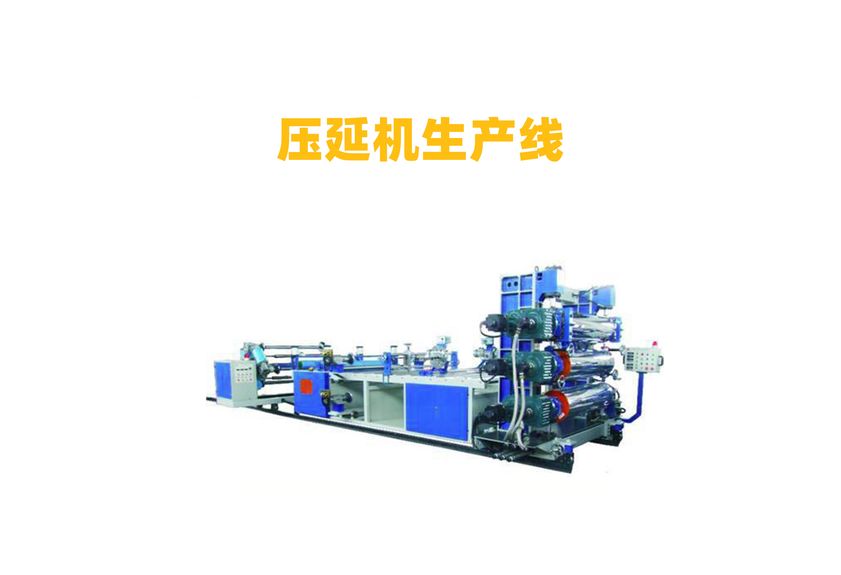

There are several types of silver foil rolling machines available in the market, each with its unique features and capabilities. Here are some of the most common types:

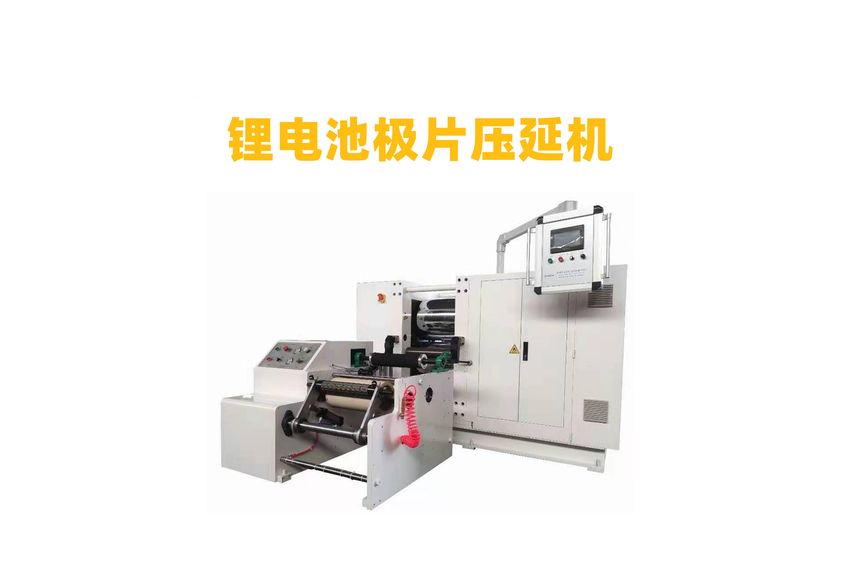

1. Sheet Rolling Machine: This type of machine is used to roll sheets of silver foil into thinner sheets. It is ideal for small-scale production and can be easily customized to meet specific requirements.

2. Cylinder Rolling Machine: This machine is designed to roll cylinder-shaped silver foil into strips or rolls. It is commonly used in the electronics industry for circuit board coatings and other applications.

3. Sheet Rolling Machine with Die Grinder: This combination machine is perfect for those looking to produce precise shapes from their silver foil sheets. It includes a die grinder that allows for the creation of intricate designs on the finished product.

Applications of Silver Foil Rolling Machines:

Silver foil rolling machines are widely used in various industries due to their ability to produce high-quality, uniformly coated products. Some of the common applications include:

1. Jewelry Manufacturing: Silver foil rolling machines are essential tools for creating beautiful and durable jewelry pieces. They are used to coat metal surfaces with silver foil, which enhances the shine and durability of the jewelry.

2. Electronics Manufacturing: In the electronics industry, silver foil rolling machines are used to coat circuit boards with silver to improve electrical conductivity and reduce noise. They are also used in the manufacture of other electronic components, such as capacitors and resistors.

3. Packaging Industry: Silver foil rolling machines are used in the packaging industry to create protective films for fragile items, such as glassware and electronic devices. They also provide a sleek and elegant look to packaging materials.

Tips for Maintaining Silver Foil Rolling Machines:

To ensure that your silver foil rolling machines run smoothly and efficiently, it is important to follow these maintenance tips:

1. Regular Cleaning: Regular cleaning of the machine's interior and exterior is essential to prevent buildup of dust and debris that can affect the quality of the produced products. Use a soft brush or cloth to remove any dirt or grime.

2. Lubrication: Proper lubrication of the moving parts of the machine is crucial for preventing wear and tear. Use a suitable lubricant specifically designed for the machine's type and application.

3. Regular Tuning: Regular tuning of the machine's settings is necessary to ensure that it produces consistent results and meets the desired specifications. Check the machine's manual for recommended tuning procedures.

1. Silver Foil Rolling Machines

2. Jewelry Manufacturing

3. Electronics Manufacturing

4. Packaging Industry

5. Maintenance Tips

This article provides an in-depth exploration of the art of silver foil rolling machines, highlighting their diverse applications in various industries. From jewelry manufacturing to electronics and packaging, these machines play a crucial role in producing high-quality, uniformly coated products. By following proper maintenance tips, you can ensure that your silver foil rolling machines run smoothly and efficiently, yielding consistent results every time. With their versatile capabilities and wide range of applications, silver foil rolling machines are an essential tool for anyone looking to produce high-quality products.