The Role of Extrusion Machines in the Manufacturing of Cables and Wires

Cables and wires are essential components of modern electrical systems, providing power and communication pathways. The manufacturing process of these materials involves several stages, including extrusion, which is a crucial step in the production line. In this article, we will discuss the importance of extrusion machines in the manufacture of cables and wires, their types, and how they contribute to the overall quality and efficiency of the production process.

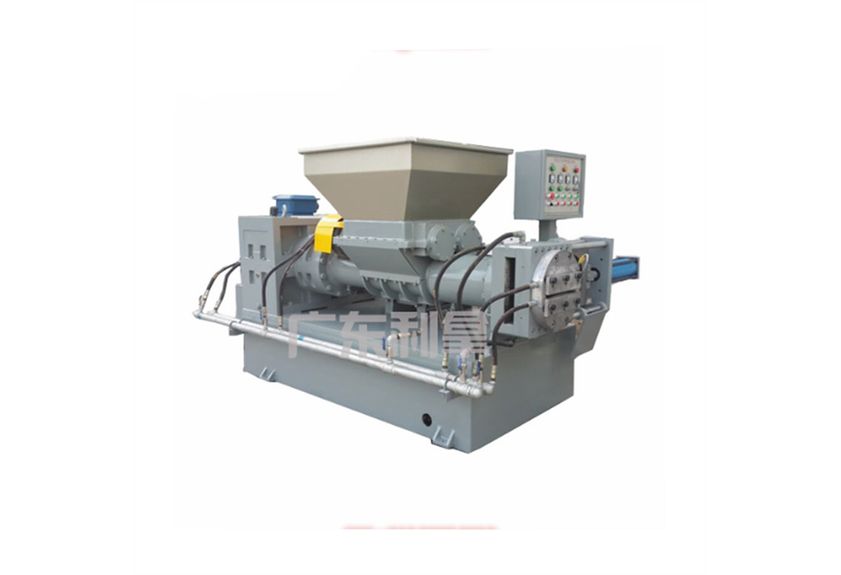

Firstly, let's understand what an extrusion machine is. An extrusion machine is a device used for shaping materials into desired shapes by forcing them through a die or mold. In the case of cables and wires, the extrusion machine is responsible for forming the outer layer of the material into a uniform and consistent thickness. This process is crucial as it ensures that the cable or wire has a smooth surface and can withstand the stresses associated with electrical current flow.

There are different types of extrusion machines used in the manufacturing of cables and wires, each with its unique features and advantages. Here are some of the most common types:

1. Rotary Extrusion Machine: This type of machine uses rotating rolls to extrude the material. It is commonly used for producing wires and cables with a high degree of uniformity in the cross-sectional shape.

2. Vertical Extrusion Machine: This type of machine is designed to produce wires and cables with a more complex cross-sectional shape. It uses a vertical shaft to force the material through the die, resulting in a tapered profile.

3. Horizontal Extrusion Machine: This type of machine is ideal for producing wires and cables with a flat cross-sectional shape. It uses horizontal rollers to extrude the material, resulting in a uniform thickness throughout the length of the product.

The importance of extrusion machines in the manufacturing of cables and wires cannot be overstated. They play a critical role in ensuring that the final product meets the required specifications and standards. By using advanced technology and innovative design, manufacturers can optimize the production process and reduce costs while maintaining the highest level of quality.

In conclusion, extrusion machines are essential tools in the manufacturing industry, particularly in the production of cables and wires. From rotary to vertical and horizontal machines, there are various types available that cater to different needs and requirements. By understanding the different types and their benefits, manufacturers can make informed decisions about which machine to use and how to optimize the production process.