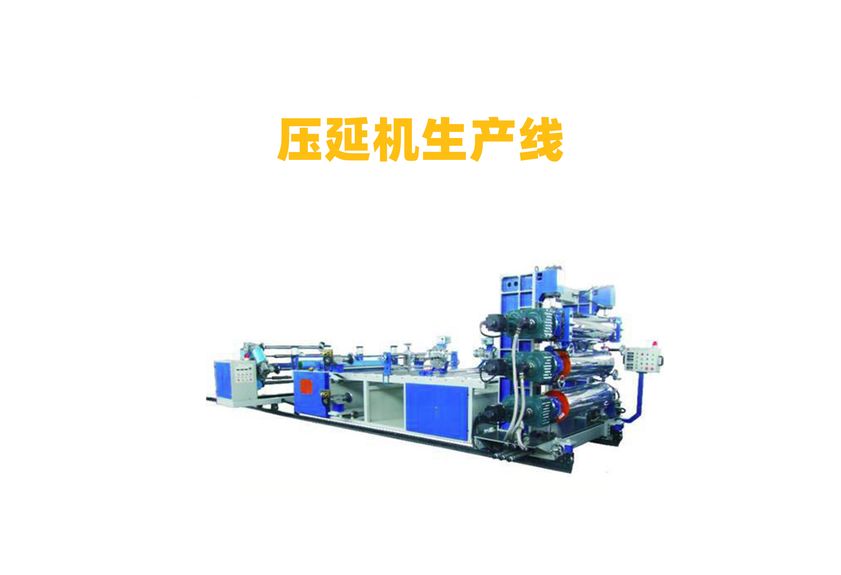

Liquid Thermal Conductive Silicone Roll Press

The liquid thermal conductive silicone roll press is a crucial tool in the manufacturing industry, particularly in the electronics and automotive sectors. This machine is designed to produce high-quality silicone sheets that have excellent thermal conductivity, making them ideal for use in heat dissipation applications.

The liquid thermal conductive silicone roll press consists of several key components, including a roller assembly, a heating system, and a cooling system. The roller assembly is made up of two main parts: the upper roller and the lower roller. These rollers are mounted on a shaft and rotate at high speeds to form the silicone sheet. The heating system is responsible for melting the silicone material, while the cooling system helps to maintain the temperature during the process.

One of the key benefits of using this machine is its ability to produce silicone sheets with precise thickness and uniformity. The roller assembly is precisely controlled, allowing for consistent results every time. Additionally, the machine's advanced control system ensures that the silicone sheet is produced within a specific temperature range, which is critical for maintaining its thermal conductivity.

Another advantage of this machine is its flexibility. It can be easily adapted to different types of silicone materials, including those with different melting points or viscosities. This makes it a versatile tool for a wide range of applications, from electronics to automotive.

In conclusion, the liquid thermal conductive silicone roll press is an essential tool for any manufacturer looking to produce high-quality silicone sheets with excellent thermal conductivity. Its precision control, versatility, and ability to produce consistent results make it a valuable asset in the manufacturing industry.