"The Role of Talc Powder Granulators in the Manufacturing Industry

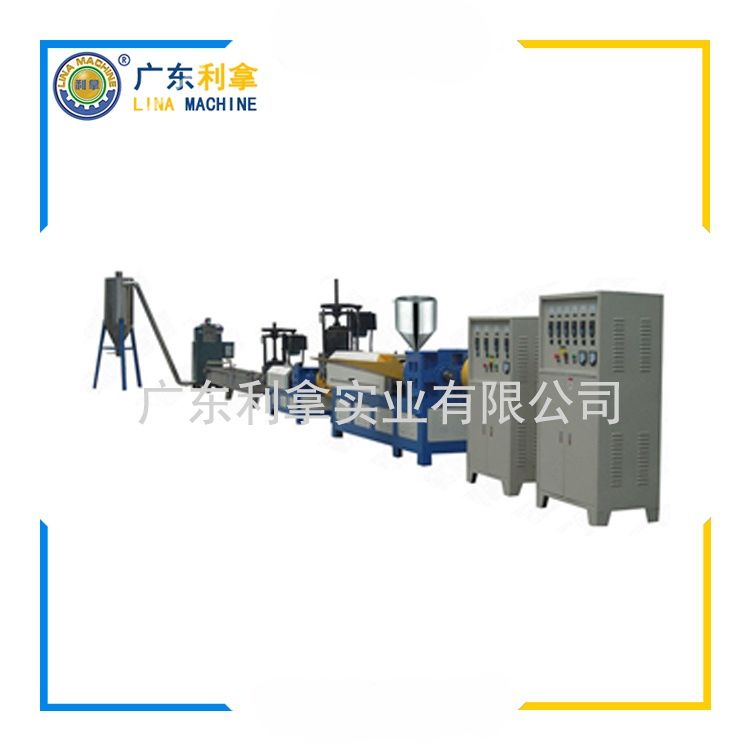

Talc powder granulators are essential tools in the manufacturing industry, particularly in the production of various types of products that require a fine and uniform distribution of talc powder. These machines are designed to process talc raw materials into granulated form, which is then used as a filler or extender in various applications such as cosmetics, pharmaceuticals, and food products. The granulators are highly efficient in their operations, producing high-quality granules with consistent size and shape.

One of the main advantages of using talc powder granulators is their ability to handle a wide range of talc raw materials. These machines are capable of processing different types of talc, including natural and synthetic varieties, without affecting the quality of the final product. This flexibility makes them ideal for manufacturers who need to produce customized products based on specific requirements.

Another significant benefit of these granulators is their ability to produce granules of varying sizes and shapes. By adjusting the parameters of the machine, manufacturers can easily control the size and shape of the granules produced, allowing them to meet the specific needs of their customers. This feature is particularly useful for industries that require precise control over the size and shape of their products.

In addition to their technical advantages, talc powder granulators also have a positive impact on the environment. By reducing the amount of waste generated during the production process, these machines help to minimize the environmental impact of the manufacturing industry. This is particularly important in today's world, where sustainability is becoming increasingly important for businesses.