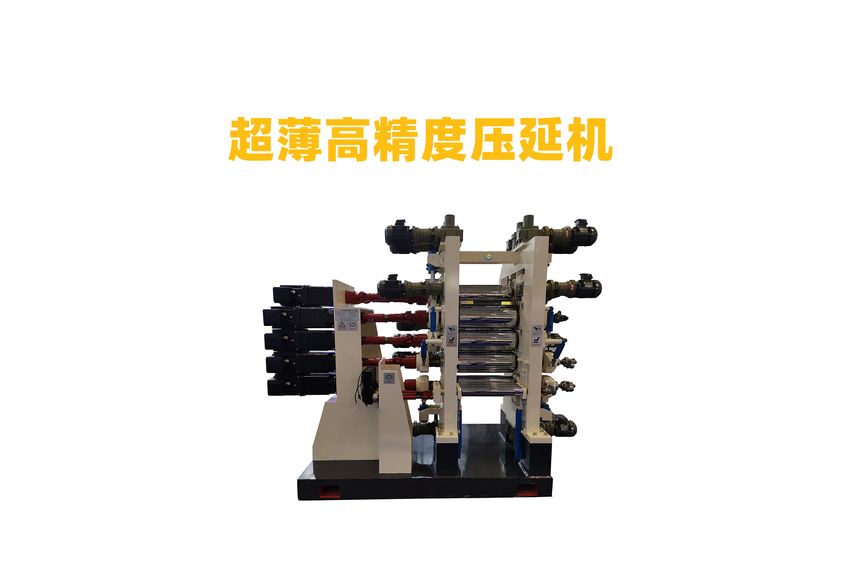

The Art of Thin Film Rolling Machines

The thin film rolling machine is a crucial tool in the manufacturing industry, particularly in the electronics and semiconductor sector. It is a versatile piece of machinery that can be used to produce a wide range of materials, including plastics, metals, and ceramics. In this article, we will explore the different types of thin film rolling machines, their applications, and some tips for maintaining them effectively.

There are several types of thin film rolling machines, each with its unique features and capabilities. One common type is the sheet-fed roller, which is used to roll sheets of material into thin films. Another type is the ribbon-fed roller, which is used to roll ribbon-shaped materials into thin films. There are also specialized machines designed for specific applications, such as those used to manufacture flexible circuit boards or solar panels.

One of the key advantages of thin film rolling machines is their ability to produce high-quality films with minimal defects. This is achieved through precise control over the temperature and pressure applied during the rolling process. Additionally, thin film rolling machines are often equipped with advanced sensors and algorithms that allow for real-time monitoring and adjustment of parameters, ensuring consistent results every time.

In addition to their technical advantages, thin film rolling machines have a wide range of applications in various industries. For example, they are commonly used in the production of electronic devices such as smartphones, tablets, and laptops. They are also essential in the manufacturing of solar panels, where thin films are used to create efficient solar cells. Furthermore, thin film rolling machines are used in the production of medical devices, automotive parts, and other high-tech products.

To ensure the longevity and efficiency of thin film rolling machines, it is important to follow proper maintenance procedures. This includes regular cleaning and lubrication of the machine's moving parts, as well as inspecting for any signs of wear or damage. Additionally, it is important to keep track of the machine's performance data, such as temperature and pressure readings, to identify any issues early on and prevent potential problems from becoming more serious.

In conclusion, thin film rolling machines are an essential part of the manufacturing industry, providing high-quality films with minimal defects and a wide range of applications in various industries. By following proper maintenance procedures, businesses can ensure the longevity and efficiency of these machines, allowing them to continue producing quality products for years to come.