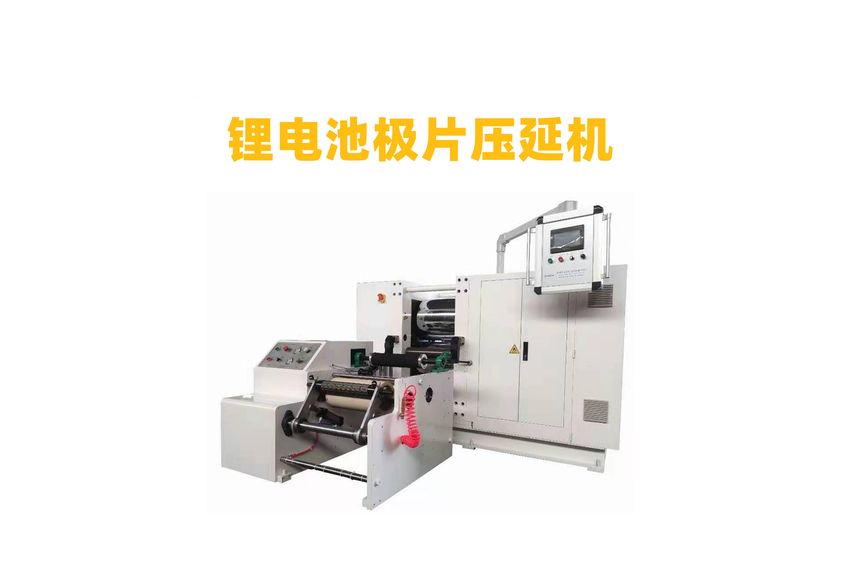

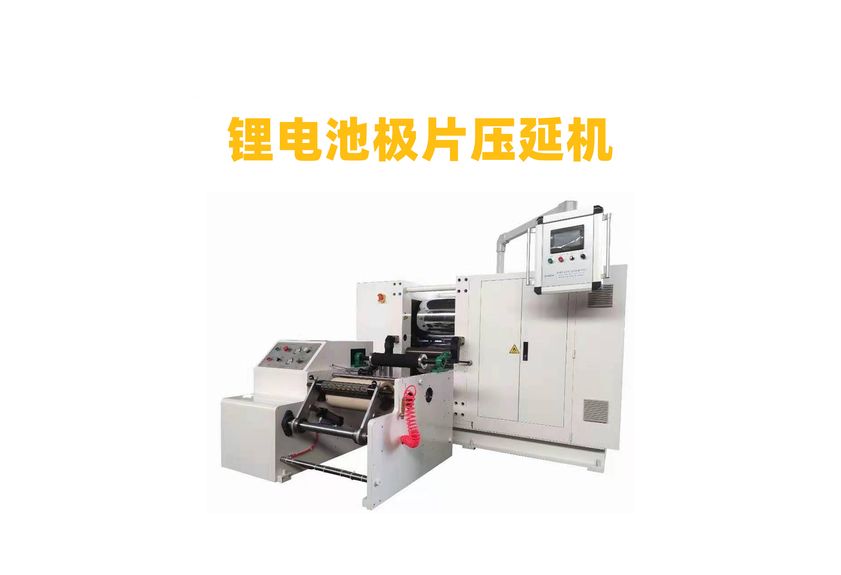

Understanding the Polytetrafluoroethylene Rolling Mill

The polytetrafluoroethylene (PTFE) rolling mill is a crucial tool in the manufacturing industry, particularly in the production of high-performance materials such as hoses, seals, and filters. This machine uses PTFE sheets to create uniform layers of material that are then rolled into tubes or rods. The process involves heating the PTFE sheets to a high temperature, which causes them to soften and flow easily. The sheets are then laid out on a metal platen and pressed together using a roller system. As the sheets move through the rollers, they are forced together and cooled down, creating a strong bond between the layers. The resulting product is a seamless tube with a smooth surface and excellent resistance to wear and tear.

In addition to its use in manufacturing, the PTFE rolling mill has many other applications in various industries. For example, it can be used to produce medical devices such as catheters and implants, as well as in the automotive industry for seals and gaskets. The machine's ability to produce high-quality products at a low cost makes it an attractive option for businesses looking to streamline their manufacturing processes.

1. Polytetrafluoroethylene rolling mill

2. Manufacturing industry

3. High-performance materials

4. Hoses, seals, filters

5. Automotive industry

This article provides an in-depth understanding of the Polytetrafluoroethylene (PTFE) rolling mill, a crucial tool in the manufacturing industry that produces high-quality materials such as hoses, seals, and filters. The process involves heating PTFE sheets to a high temperature, which causes them to soften and flow easily. The resulting product is a seamless tube with a smooth surface and excellent resistance to wear and tear. The PTFE rolling mill has many other applications in various industries, making it an attractive option for businesses looking to streamline their manufacturing processes.