The Art of Rubber Additive Particle Making Machinery

In the realm of polymer processing, the role of additives is undeniable. These are substances that are added to a polymer matrix to enhance its properties, such as tensile strength, flexibility, and resistance to aging. One of the most critical components in this process is the rubber additive particle making machine. This sophisticated machinery plays a crucial role in the production of high-quality additive particles that are essential for various industrial applications.

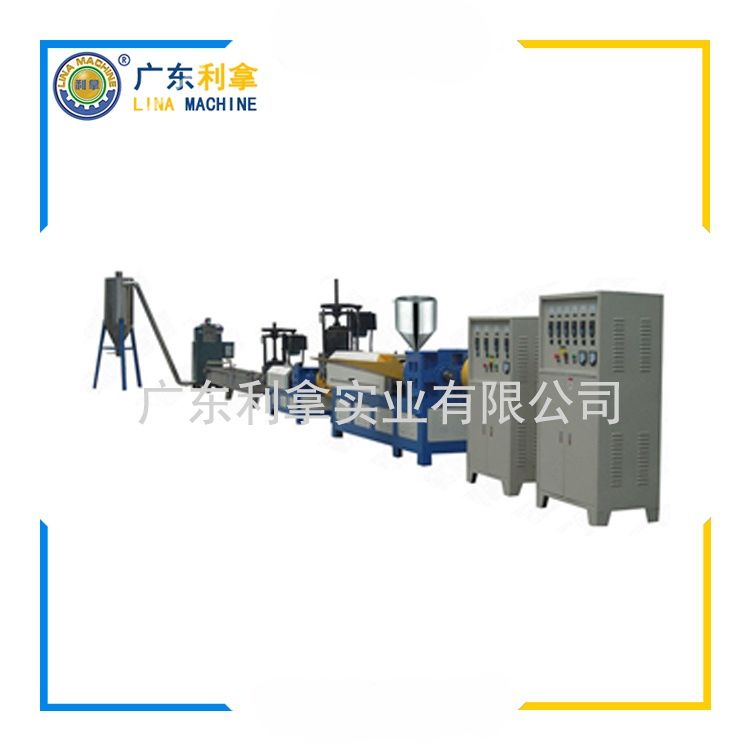

The rubber additive particle making machine is a complex piece of equipment that involves several stages of operation. At the outset, raw materials such as natural or synthetic rubber compounds are fed into the system. These compounds undergo a series of chemical reactions to produce a homogeneous mixture. The resulting mixture is then extruded through a die, which forces it into small pellets or particles. These particles are then dried and cooled to remove any residual moisture and to stabilize their structure.

The design of the rubber additive particle making machine is optimized for efficiency and consistency. The machine features advanced technology that ensures uniform distribution of the additive particles throughout the entire production process. This results in consistent quality and repeatability, which are essential for industrial applications.

One of the key advantages of using the rubber additive particle making machine is its ability to produce particles with controlled size and shape. This allows for precise control over the final product's performance, which is crucial in industries where specific properties are required. Additionally, the machine's ability to handle a wide range of raw materials makes it versatile and suitable for a variety of applications.

In conclusion, the rubber additive particle making machine is a vital component in the production of high-quality additive particles. Its advanced technology and ability to produce consistent products make it an essential tool for industries that rely on these additives for their products' performance. As the demand for high-quality additives continues to grow, the importance of this machinery will only increase.