Understanding the Functionality of Fluorocarbon Rubber Roll Press

Fluorocarbon rubber, also known as fluorocarbon or FKM, is a type of high-performance elastomer that has been extensively used in various industrial applications due to its exceptional properties. One such application is the use of fluorocarbon rubber in the production of fluorocarbon rubber rollers, which are crucial components in the manufacturing process of various materials such as polyurethane foam, silicone rubber, and other thermoplastics.

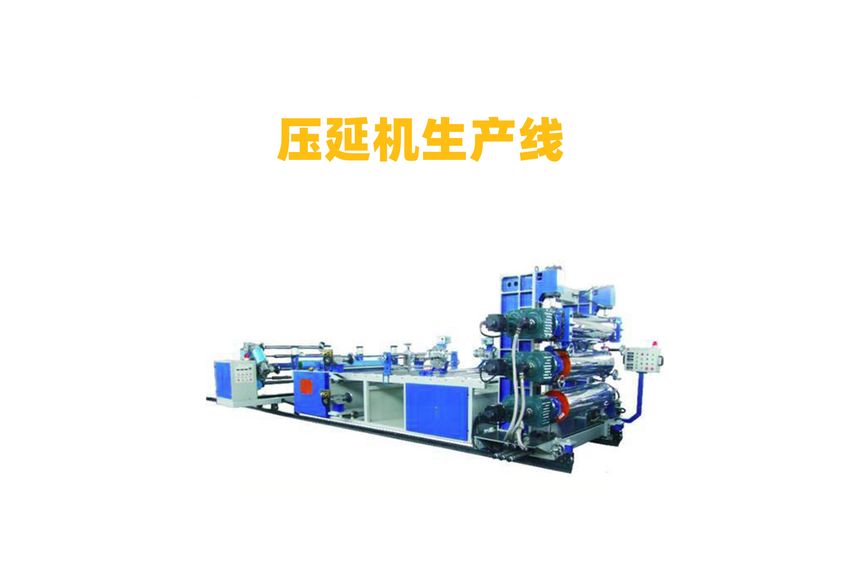

The function of a fluorocarbon rubber roller press is to provide a uniform and consistent surface for the material being processed. This is achieved through the use of a roller that is coated with a layer of fluorocarbon rubber. The roller press consists of a motorized drive system that moves the roller across the material being processed, while the fluorocarbon rubber layer provides the necessary friction and pressure to ensure a smooth and even surface.

One of the key advantages of using fluorocarbon rubber rollers is their ability to withstand high temperatures and pressures. This makes them ideal for use in environments where temperature and pressure changes can occur, such as in automotive, aerospace, and medical equipment industries. Additionally, fluorocarbon rubber is highly resistant to chemicals and solvents, making it an ideal choice for use in chemical processing and pharmaceutical industries.

In conclusion, fluorocarbon rubber rollers are a critical component in the manufacturing process of various materials, including polyurethane foam, silicone rubber, and thermoplastics. Their ability to withstand high temperatures and pressures, as well as their resistance to chemicals and solvents, make them an ideal choice for use in a variety of industrial applications.