A Comprehensive Guide to Aluminum Foil Rolling Machines

Aluminum foil rolling machines are essential tools in the manufacturing industry, particularly in the production of aluminum foil packaging materials. These machines are designed to roll aluminum foil into sheets with a consistent thickness and width, which is crucial for various applications such as food wraps, gift wrapping, and cosmetic packaging. In this article, we will explore the different types of aluminum foil rolling machines, their features, and how they can benefit your business.

1. Traditional Rolling Mills:

These machines are the most common type of aluminum foil rolling machine used in industrial settings. They consist of a large roller that rotates around a stationary axis, which applies pressure to the aluminum foil as it passes through the roller. The roller is usually made of high-strength steel and has a smooth surface to ensure even thickness and quality of the rolled foil. Traditional rolling mills are suitable for small to medium-sized factories and can produce up to 2000 square meters of foil per hour.

2. Automatic Rolling Lines:

These machines are designed to automate the process of rolling aluminum foil, reducing labor costs and increasing efficiency. Automatic rolling lines consist of several stations, each responsible for different stages of the rolling process. For example, one station may be responsible for feeding the foil into the machine, another for applying pressure, and another for removing the rolled foil. Automatic rolling lines are ideal for larger factories or those looking to increase production capacity.

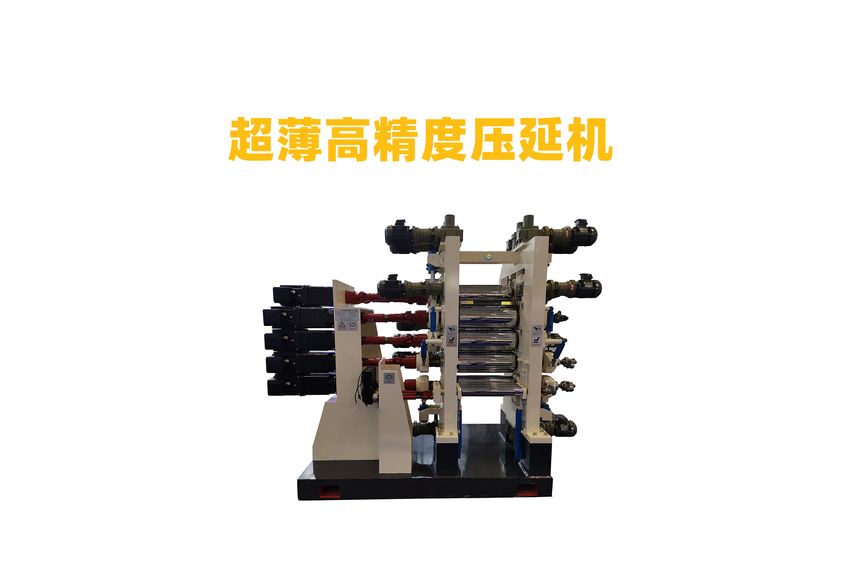

3. CNC Rolling Machines:

CNC (Computer Numerical Control) rolling machines are highly precise and can produce foil with a very thin thickness. These machines use computer-controlled software to precisely control the rolling process, resulting in uniformly thick and thin foil. CNC rolling machines are typically used in research and development settings or by companies that require high-quality products.

4. Rolling Presses:

Rolling presses are specialized machines that are specifically designed for rolling aluminum foil into sheets. These presses have a unique design that allows for precise control over the rolling process, resulting in high-quality foil. Rolling presses are ideal for small to medium-sized factories that need to produce high-quality aluminum foil for specific applications.

1. Aluminum Foil Rolling Machines

2. Traditional Rolling Mills

3. Automatic Rolling Lines

4. CNC Rolling Machines

5. Rolling Presses

This article provides an in-depth analysis of the different types of aluminum foil rolling machines available in the market, including traditional rolling mills, automatic rolling lines, CNC rolling machines, and rolling presses. Each type of machine is explained in detail, highlighting their key features and benefits, making them suitable for different production needs. By understanding the advantages of each type of machine, businesses can choose the right equipment to meet their production requirements and optimize their operations.