The Role of the Five-Roll Rolling Press in Metal Forming

The five-roll rolling press is a versatile and efficient tool used in metal forming processes. It is a type of press that uses five rollers to roll a workpiece into its desired shape. This machine is widely used in industries such as automotive, aerospace, and construction, where it is essential for shaping various components.

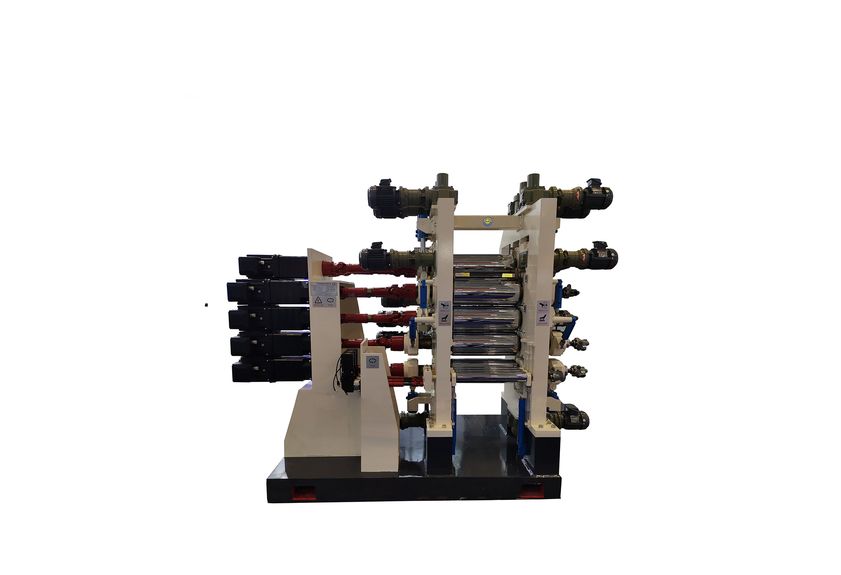

The five-roll rolling press consists of a main frame, which supports the workpiece and the rollers, and a control panel that controls the speed and direction of the rollers. The rollers are made of high-quality steel and are arranged in a way that allows them to exert even pressure on the workpiece. The rollers are connected to a motor that drives them at different speeds, depending on the desired shape of the workpiece.

One of the key advantages of the five-roll rolling press is its ability to produce complex shapes with precision. The rollers are precisely positioned and aligned, allowing for accurate cutting and shaping of the workpiece. This makes it an ideal choice for manufacturing parts with intricate designs, such as gears, valves, and piston rings.

Another benefit of the five-roll rolling press is its ability to handle a wide range of materials. It can be used to form steel, aluminum, copper, and other metals, making it a versatile tool for various industries. Additionally, the machine's ability to adjust the pressure and speed of the rollers allows for customization of the final product, making it suitable for a variety of applications.

In conclusion, the five-roll rolling press is a crucial tool in metal forming processes. Its ability to produce complex shapes with precision and its versatility make it an essential piece of equipment in many industries. By leveraging its capabilities, manufacturers can create parts with superior quality and performance, ultimately driving innovation and growth in their respective fields.