The Flexible Plastic Granulation Production Line

The flexible plastic granulation production line is a crucial component in the plastics industry, responsible for transforming raw plastic materials into granulated products. This article will provide an overview of the key components and functions of this production line, as well as its advantages and applications in various industries.

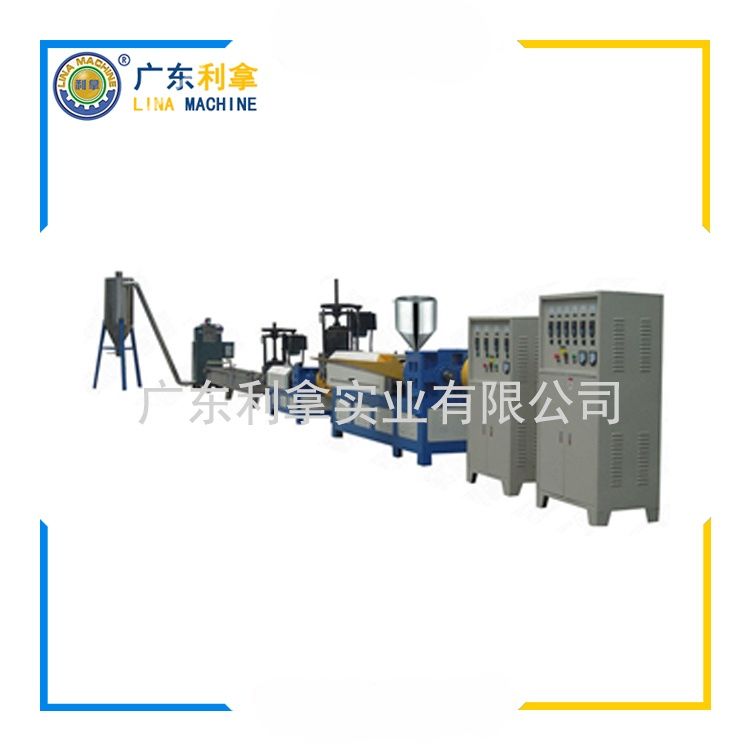

The flexible plastic granulation production line consists of several key components, including the granulator, screw extruder, melting system, cooling system, and packaging system. The granulator is responsible for breaking down the raw plastic material into smaller pieces, while the screw extruder heats and mixes the material. The melting system ensures that the material is melted to the desired consistency, while the cooling system cools the material down before it enters the granulator. Finally, the packaging system packages the granulated product for further processing or sale.

One of the main advantages of the flexible plastic granulation production line is its ability to produce a wide range of granulated products with different sizes and shapes. This flexibility allows manufacturers to customize their products according to customer requirements, which can lead to increased sales and market share. Additionally, the production line's high efficiency and low energy consumption make it an attractive option for businesses looking to reduce costs and improve sustainability.

Industries that benefit from using the flexible plastic granulation production line include food and beverage packaging, automotive parts, medical equipment, and electronics. For example, in the food and beverage industry, granulated plastic bags and containers are used to package food products, making them more durable and resistant to damage during transportation. In the automotive industry, granulated plastic parts such as fuel tanks and engine mounts are essential for ensuring safety and reliability. In the medical industry, granulated plastic implants are used to replace damaged bones and joints, providing patients with improved mobility and comfort. Finally, in the electronics industry, granulated plastic components such as connectors and housings are used to create innovative devices that meet specific performance requirements.

In conclusion, the flexible plastic granulation production line plays a critical role in the plastics industry by enabling manufacturers to produce a wide range of granulated products with high efficiency and low energy consumption. Its flexibility and customizability make it an attractive option for businesses looking to meet customer requirements and increase market share. As the demand for sustainable and eco-friendly products continues to grow, the flexible plastic granulation production line will continue to be an important tool in the plastics industry.